- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

for providing digital isolation I am planning to use ISO7741/ ISO7841 with analog SPI ADC ADS1018IDGST. can you please suggest your opinions and any specific recommendations for circuit designs.

Hi Bincy,

We will get back to you in a couple of days as we are out of office due to the 4th of July holiday. Thanks!

Best Regards,

Angel

Dear Team,

Thank you for your response . I will wait for your response.

Also can you please suggest alternate for ADS1018-Q1 pin to pin compactible

Hi Bincy VK,

The only other device that is pin compatible with the ADS1018-Q1 is the ADS1118-Q1, the 16-bit version

What circuit designs are you looking for? ADC + digital isolation? If so, you just connect the appropriate communication pins to the isolator pins, there isn't really a circuit / schematic to recommend

If you need something else, please be very specific with your questions

-Bryan

thank you for your response. I need digital isolation for SPI communication and my circuit is designed for automotive applications. so do you have any specific recommendations for digital isolator series for this requirements

Hi Bincy VK,

Can you please post your question in the Isolation Forum if your question is about which isolator to use. That team will know better which device is best to recommend for your application. This forum is more if you had a question about the ADC operation.

-Bryan

Hello Bryan,

I have some queries regarding this ADS1018-Q1 ADC. for EMC point of view I am Applying 4KV burst, +/-8KV ESD contact discharge signal to my design. Also the ADC GND directly coming to the picture of these EMC testing. Can you please suggest any recommended EMC filters there for this test cases.

Best Regards,

Bincy V K

Hi Bincy VK,

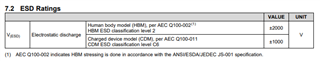

The ESD ratings for ADS1018-Q1 can be found in section 7.2 of the data sheet:

Note that this device is rated to 2kV for the HBM model in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Applying electrostatic discharge larger than the device rating may result in damage to the device.

To protect against a higher ESD voltage, it may help to have external protection for the device. TVS, Schottky diodes, or extra series resistance can be added to the analog inputs of the device.

The problem with adding too much input resistance is the amount of error added to the measurement. There is a certain amount of bias current being drawn from the ADS1018 due the switched capacitor input stage. Adding a large value resistance in series with the input will cause an error due to the voltage drop across the resistor. It is best to keep this input series resistance to 1k or below to avoid this measurement error.

From a rule of thumb and EMI/EMC standpoint, it is recommended tying your boards' GND or return to the same voltage or reference.

It might be helpful to check out this app note where we look into EMC compliance testing. It might give you some other tips about layout and other helpful information:

EMC Compliance Testing for Precision ADC Systems (Rev. A)

Here are some additional resources that might help:

Getting started with interface protection | TI.com

Circuit for protecting ADS131M0x ADC from electrical overstress

Design considerations for system-level ESD circuit protection

Best Regards,

Angel