Other Parts Discussed in Thread: ADS1220, ADS131M02

Tool/software:

Hello,

I am currently working with the ADS1115 ADC and STM32f4, in my project to measure current changes across an AC load using a CT sensor. I have encountered fluctuations in ADC readings when using single-ended mode, but the readings are stable in differential mode. Below are the details of my configuration and issue:

in my project to measure current changes across an AC load using a CT sensor. I have encountered fluctuations in ADC readings when using single-ended mode, but the readings are stable in differential mode. Below are the details of my configuration and issue:

Configuration:

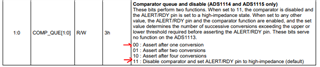

I need to operate ADC in continous mode not in single shot mode so using conversion ready signal in ALERT/READY pin i am reading the value stored in conversion register. According to the information in data sheet i setted the High_threshold register msb with 1 (the value i wrote is 0x8000) and low threshold register MSB to 0 (the value i wrote to this register is 0x0000)

-

ADS1115 Settings:

- OS bit: 0 (conversion is not in progress)

- MUX[14:12]:

- For differential mode (the following i checked with):

001: AINP = AIN0, AINN = AIN3010: AINP = AIN1, AINN = AIN3011: AINP = AIN2, AINN = AIN3

- For single-ended mode:

100: AINP = AIN0, AINN = GND101: AINP = AIN1, AINN = GND110: AINP = AIN2, AINN = GND111: AINP = AIN3, AINN = GND

- For differential mode (the following i checked with):

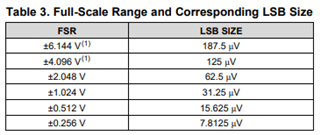

- FSR: checked with 2.048V and 4.096V and the formula used to convert the ADC value is voltage = ((adc_value * FSR * 1000) / 32768);

- Data Rate: 128SPS

- Comparator Mode: Zero

- Comparator Polarity: One

- Comp_que: Set to 00 (no comparator)

-

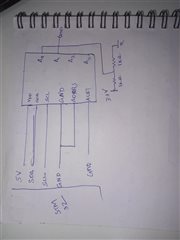

Hardware Setup:

- VDD: 5V connected to ADS1115

- Ground: Common ground across all components (ADS1115, STM32 microcontroller, and voltage divider)

- Input Voltage for Testing: 3.3V from the STM32 microcontroller, stepped down to 1.651V using a voltage divider circuit (2 resistors, each 1kΩ).

- Test Signals: Used a multimeter to verify input voltage at 1.651V.

Observations:

-

Fluctuations in Single-Ended Mode:

- When I apply 1.651V to the input (AIN0), I observe fluctuations in the ADC readings. The values are not constant and vary in a range like 1.601V, 1.624V, and 1.532V at different times. I am difficult to predict the variation.

-

Offset Readings:

- When I check the ADC value with 0V input (to measure offset), I observe fluctuating negative values like -0.101V, -0.92V, and -0.27V at different times. These values are inconsistent, making it difficult to calibrate the offset error.

-

Stable Readings in Differential Mode:

- When I switch to differential mode (AINP = AIN0, AINN = AIN3), the ADC shows stable and correct readings: 1.653V when applying the input voltage and 0V when measuring the offset by connecting 0V.

Questions:

- Why am I observing these fluctuations in single-ended mode?

- What could be causing the offset errors in single-ended mode, and how can I correct them?

- Is there a way to stabilize the ADC readings in single-ended mode, similar to the stable readings in differential mode?

- How can I add the offset values for proper calibration in my application?

Any help, suggestions, or guidance on how to resolve this issue would be greatly appreciated!

- When I switch to differential mode (AINP = AIN0, AINN = AIN3), the ADC shows stable and correct readings: 1.653V when applying the input voltage and 0V when measuring the offset by connecting 0V.