Tool/software:

Hi,

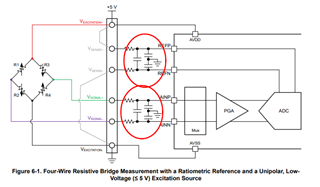

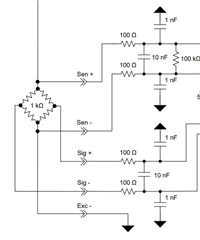

I am an electronics technician here at the University of Bristol and am supporting researchers who are wanting to build a sensing probe that measures soil impact/density using three (3) strain guage and one (1) LVDT sensor.

The probe they are sending down into the ground has a very small area for me to install my small package of electronics for them.

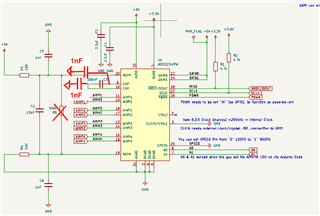

Thus, I need to use your ADS1234 PWG4 28-pin 4 channel chip.

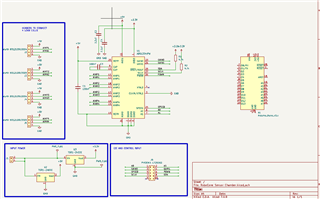

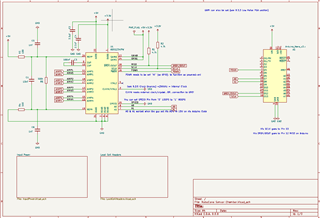

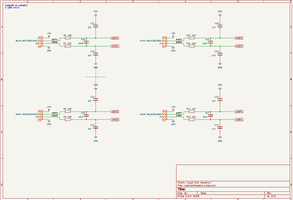

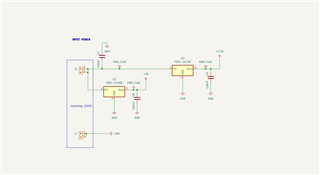

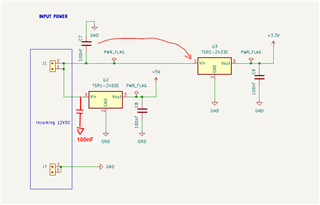

I have never worked with this chip before and could really use your help and advice on how to set it up. I wish to put it on a PCB along with an Arduino NANO and a CANBUS moduel (MCP2515), and read the incoming strain guage data off of your chip into the Arduino NANO, and then send that data to the MCP2515 canbus module out to the user.

Here is a snapshot of my design with your chip so far. But, I'm not sure if this is right?

Also, do you have any sample code for an arduino to capture the 4 channels off the chip? From what I understand, it's a custom communication protocol "SPI-like", which uses "bit-banging"?

Any support and samples you could send me would be great.

Thanks,

Hendrik

I have