Other Parts Discussed in Thread: ADS124S08,

Hi there,

I've some troubles with the measuring of three input channels where a 3-axis force sensor is connected. My general question is, how long it takes to get valid data when the input channels (differential mode) are changed or switched to another inputs? With a logic analyser by inspecting the /DRDY pin it takes independent of different configurations around 57 ms (milliseconds) but to get a good measurement with the force sensor I want the get all three channels within below 3 ms. The background is that we have to measure hundred times a second the sensor, thus each 10 ms all three channels has to be measured.

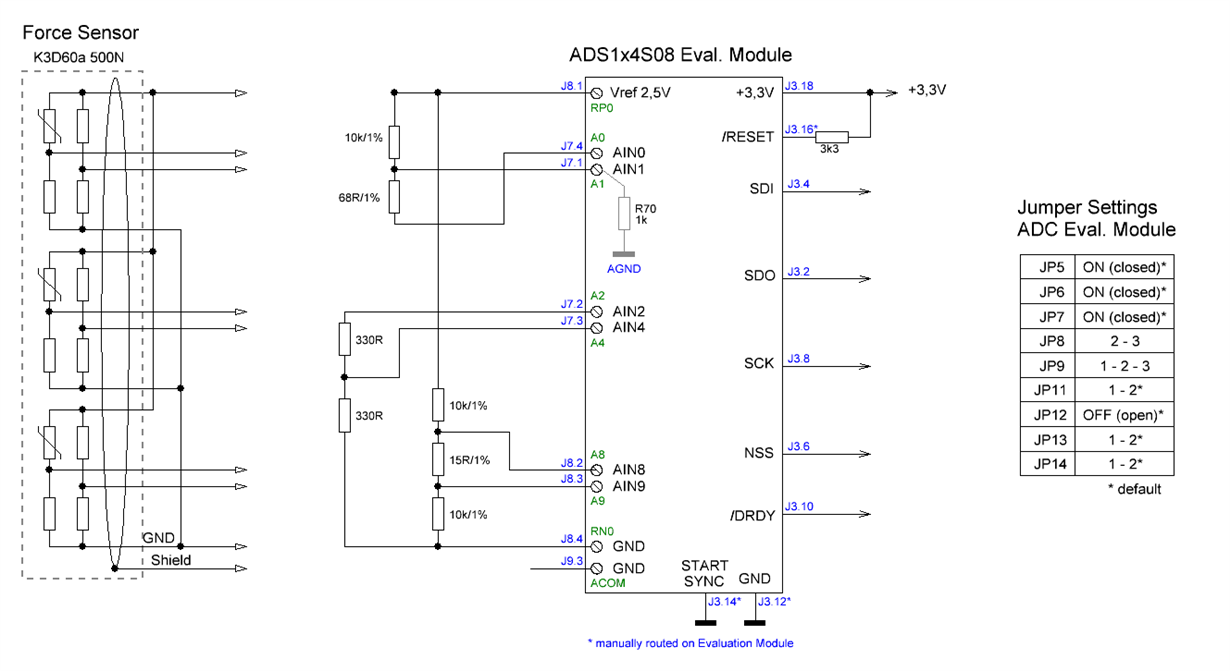

My general question is, is there any chance to do it with the ADS124S0x? In very short I only use differential inputs (A0/A1, A2/A4, A8/A9), the external on-board reference (2.5V), the internal clock, and the low latency filter. The gain is set to 128.

If you need more information about this like hardware setup or configuration and read-out procedure, please let me know. Currently I can read out the values from the three channels and calculate the voltage from this and these results meets the voltage at the inputs.