Other Parts Discussed in Thread: ADS1262

Dear Sir/Madam,

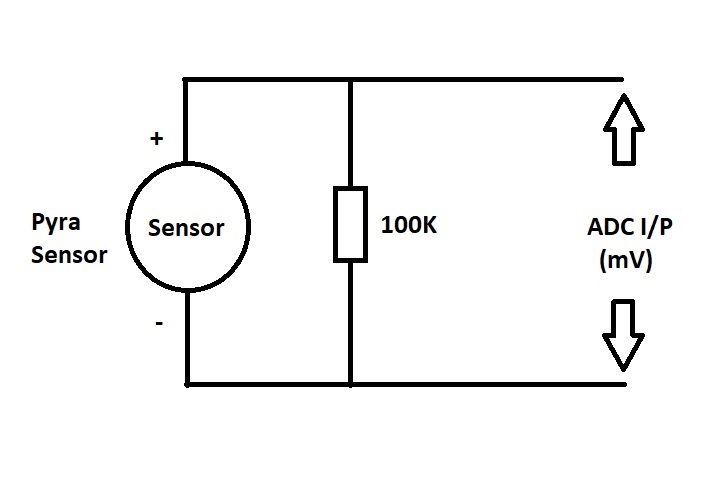

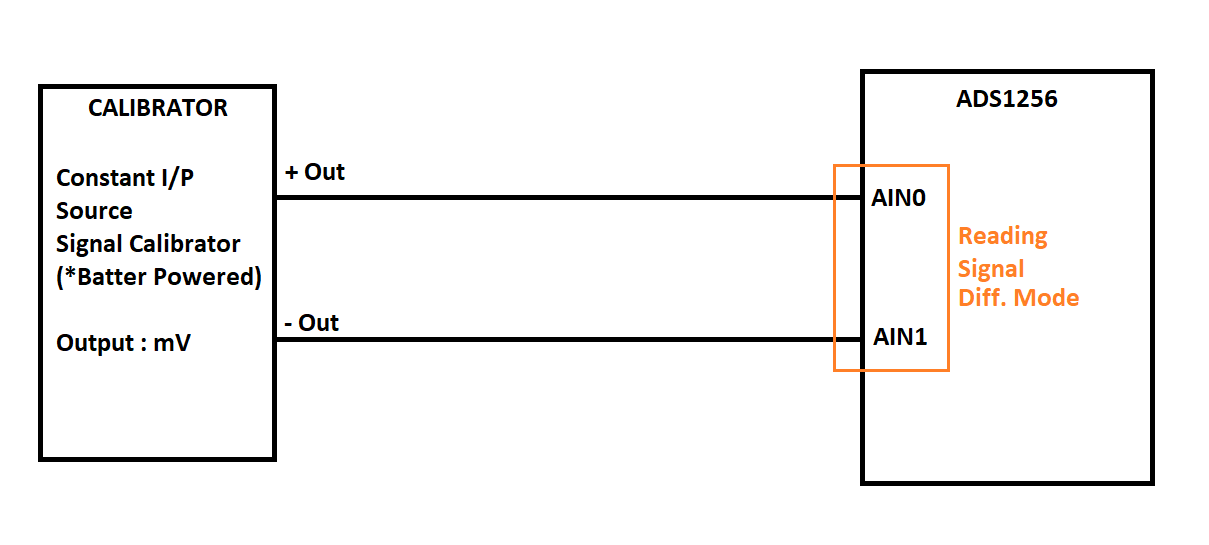

We are measuring millivolts from Pyranometer sensor (*solar radiation sensor) , model: LP Pyra 03 AV. But when we connect the sensor on the ADC input, the sensor output voltage get disturbed. for example the output voltage of the sensor when measured with Multimeter it shows 350mV but when connected to ADC it drops to 14mV. Although if we give a fixed mV signal from a calibrator instead of sensor to ADC input then it shows the correct mV reading. For confirmation we also have ADC1262EVM board and on connecting the same sensor it shows the correct voltage as shown in multimeter, here we have not observed any distortion in the sensor output or any kind of loading.

On comparing the Input circuit with ADC1262EVM board, its seems like the input signal is directly connected to ADC input. Kindly have a look on the attachment file for schematics of our ADC board.

ADC software configuration steps:

ADS1256_reset();

HAL_Delay(100);

ADS1256_WaitDRDY();

ADS1256_SetDiffChannel(adcChannel);

HAL_Delay(100);

ADS1256_WaitDRDY();

ADS1256_WriteReg(REG_DRATE, 0x13); // 10Sps

HAL_Delay(1);

ADS1256_WaitDRDY();

ADS1256_Sync();

HAL_Delay(1);

ADS1256_WaitDRDY();

status = readRegister(REG_STATUS);

HAL_Delay(1);

ADS1256_WaitDRDY();

mux = readRegister(REG_MUX);

HAL_Delay(1);

ADS1256_WaitDRDY();

dr = readRegister(REG_DRATE);

HAL_Delay(1);

ADS1256_WaitDRDY();

adcVal = readADCValue();

val = (adcVal & 0x7FFFFF);AFE-01.pdf

Do we have to add more configuration into it like activating Buffer & sensor detect etc.?

I am also attaching the schematics of our Analog Front end Circuit, kindly let us know what we are doing wrong.

Thanks & Regards,

Harinder SIngh

M2MLogger