Other Parts Discussed in Thread: DLP3010, , DLPA3005, DLPC3479, DLP4710, DLP3010LC

Tool/software:

Dear TI Engineers,

Following up on my previous case: After implementing hardware optimizations based on your local FAE's guidance post-Lunar New Year,

we successfully reduced the DMD defect rate (primarily BBF vertical lines and bright spots).

While residual issues like pixel instability remain under analysis via submitted defective units, I consider the prior case resolved.

New Technical Issue: DMD Micromirror Sticking Phenomenon

We now observe a field failure mode in 3D scanning/light-control applications, summarized below:

Failure Characteristics:

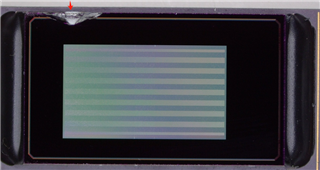

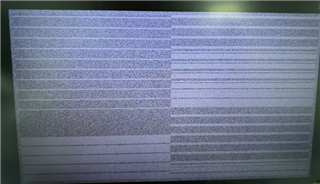

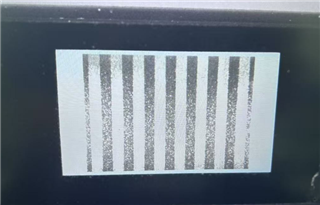

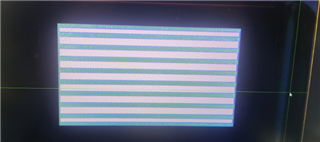

- Static micromirror pattern persists on the DMD glass surface, resembling the projected working image (line patterns).

- Partial functionality retained:

- Driver board successfully identifies the DMD (valid ID readback).

- Control commands (e.g., pattern switching) are transmitted, but micromirrors fail to flip mechanically.

- Driver board validated: Functions normally with other DMDs, confirming board integrity.

Affected Units (Case Details):

- DLP3010 (Customer A – Production Line):

- Operational duration: 1.5 years.

- Trigger cycle: 3–5 sec intervals; exposure: ~1 sec/image set.

- Optical parameters: 460nm blue LED @ 8A (high irradiance), but DMD temperature controlled (light-duty thermal load).

- DLP4710LC (Customer B – Lab Prototype):

- Operational duration: 8 months (low usage frequency; manual triggering).

- Exposure: ~400 ms/image set; 460nm blue LED @ ~1A; large DMD heatsink .

Attachments:

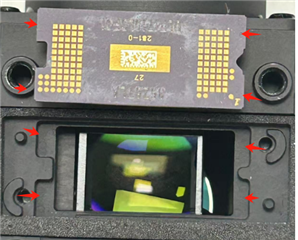

- Figure 1: DLP3010 DMD failure pattern.

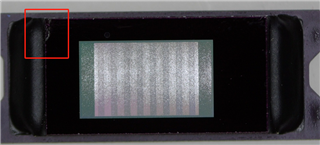

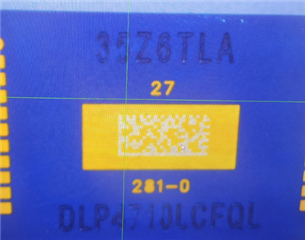

- Figure 2: DLP4710LC DMD failure pattern + batch info.

Root Cause Hypotheses & Elimination

Primary Failure Mechanisms Considered:

- Incomplete micromirror reset due to abrupt power loss during operation.

- Mechanical/electrical lock from external interference (e.g., shock, EMI).

- Internal DMD circuit fault (e.g., micromirror driver IC degradation).

External Contributing Factors Evaluated:

- a. Critical signal/power discontinuity (FPC fracture, connector dislodgement). → Eliminated:mechanical inspections confirm integrity.

- DLP4710LC uses direct FPC connection (no adapter);

- b. Extreme environmental stress (temperature/vibration). → Eliminated: Stable lab/production conditions documented.

- c. Transient noise injection (conducted/radiated). → Pending analysis

- d. DMD degradation from prolonged high-power exposure. → Low likelihood:

- DLP3010: High irradiance but low duty cycle; DLP4710LC: Low optical power.

- e. Other factors.

Critical Observations & BBF Correlation Ruling

- Excluded BBF :

- Artificially corrupting the LS signal (e.g., grounding/pulse injection) induced full DMD failure (unresponsive + BBF ID pattern visible), distinct from the current static-pattern behavior.

- DLPA3005 undervoltage protection verified:

- Driver board ensures DMD reset within <100ms during power loss.

- Simulated power interruptions only induced BBF faults, not micromirror sticking.

Technical Support Request

- Failure analysis:

- Investigate root cause(s) for the static micromirror pattern (non-BBF, non-mechanical).

- Mitigation guidance:

- Design/process recommendations to prevent recurrence (e.g., EMI hardening, power sequencing).

Your insights are critical to resolving this field reliability issue. Thank you for your prompt attention.

Best regards.