Other Parts Discussed in Thread: SN74LVC2G17, SN74AHCT125, SN74AHCT1G125

Dear TI engineer:

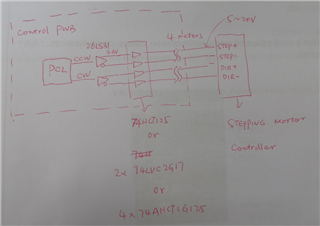

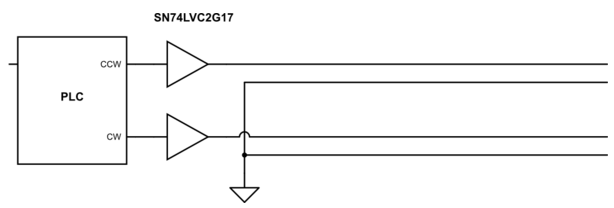

Previously, in order to connect the servo controller, CW / CCW signal about 3.6V was output by 26LS31.

At present, I want to drive the stepper motor controller. However, the input requirements of the stepping controller are 5-24v.

How to modify my CW/CCW circuit?

Are there some driver IC(output 5~24V) are recmmonded?

In addition, about 26LS31, there are some typical reference circuits about 26LS31 providded by Ti (capacitance abour VCC was founded. But resistance was not founded)?

Thanks.

Regards