Part Number: DS89C21

Hi team,

I got a question from customer.

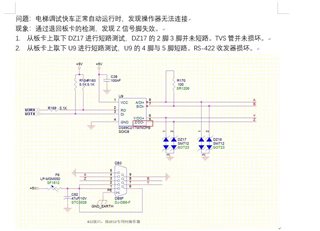

"Model: DS89C21TMX NOPB, when debugging, 5 feet were short circuited. The attached circuit diagram is for reference. Please analyze the reason.

Problem: when the elevator runs automatically in express mode, it is found that the operator cannot be connected.

Phenomenon: through board monitoring, it is found that the Z signal pin is invalid.

1. short circuit test was taken DZ17 from on board, DZ17's 2 foot and 3 pin were not short circuited, and the TVS tube was not damaged.

2. short circuit test is taken U9 from on board, U9's 4 pin and 5 pin are short circuited, and RS-422 transceiver is damaged.

"

Thank you very much for your help.

Best regards,