Part Number: TPIC8101

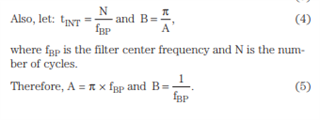

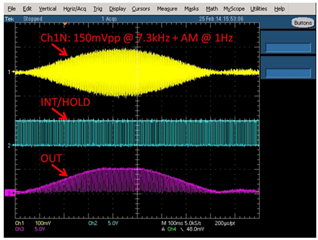

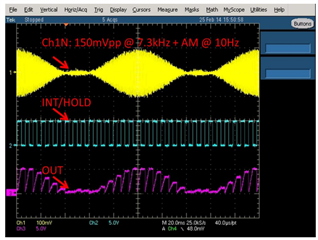

I designed in the TPIC8101 on my ECU for racing. Now I would like to start programing it. In all the datasheets/app notes it is a little unclear about does the "Integrator Time Constant" and "Gain" need to be calculated on the fly as the engine is running at different RPM. I am assuming so but, all your references are static at 3ms (5000rpm on a V8) with a 50% integration time. There is also no reference as to when the integration should start, at TDC, at 10degrees BTDC, I know it changes with every engine design but, there is no "in general" information which is what I am probably going to have to start with. I am not even sure this will work on these engines which vary from 600hp to over 4000hp. This is really for data collection and not control unless the data is clear that knock is definitely detectable.

Any help would be greatly appreciated,

Blest Regards,

Blake