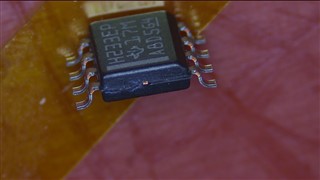

Part Number: SN65HVD233-EP

Hello Team,

We received a complain from our customer: x9 out of x9 PCAs that we built failed the test.

(Who is dedicated to oil energy services.)

After troubleshooting, the failure is from PN: SN65HVD233MDREP.

The test was passed after replacing the part with a new one.

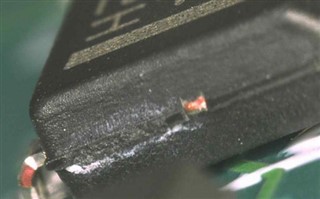

Our customer discovered some white markings/residues and fracture-like traces on the package

(We do also see the same white markings/residues on the raw material.)

Could you please help us verify what are these white markings/residues?

(It is just a cosmetic issue or it is something related to function?)

Much appreciated.