Other Parts Discussed in Thread: TFP401A

Dear TI-er.

My customer have a problem.

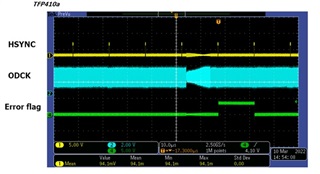

When the TFP410 of the TX stage reaches a specific temperature, the following phenomenon is observed in the RX stage.

PCB1(FPGA –> TFP410) ---> HDMI Cable ---> PCB2(TFP401A –> FPGA –> USB)

Do you recommand the solution ? (PLL Power, layout ?)