Hi Team,

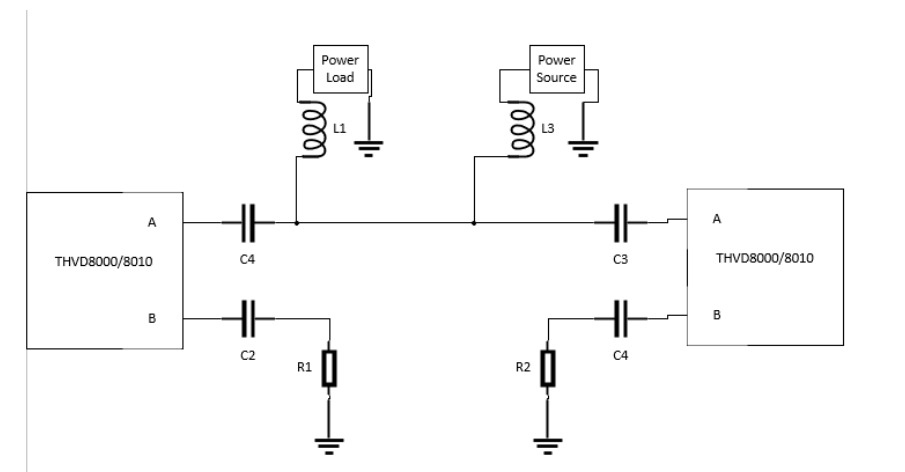

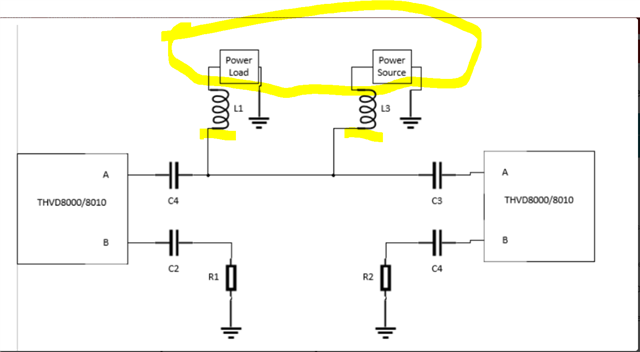

Our customer wants to use THVD8000 in one 24VAC Air Conditioner power line communication system, below is their schematic for THVD8000 section. Can you help to check if any issues and suggestions? Do we need the pull-up and pull-down resistor for A/B pins for our device?