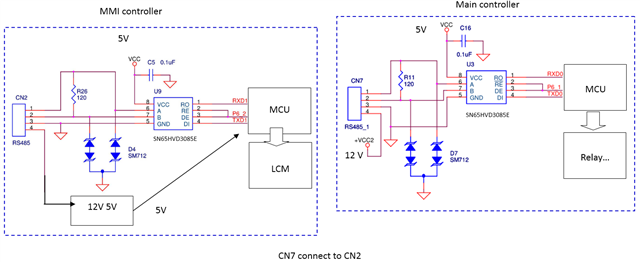

Part Number: SN65HVD3085E

As stated above, we find there are two failure modes about the RS485 ICs.

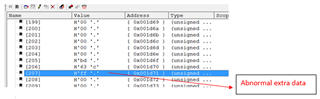

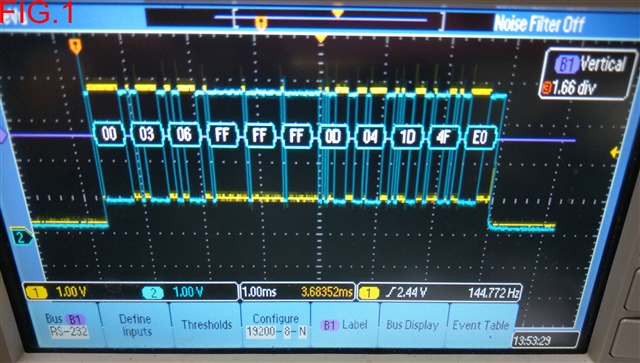

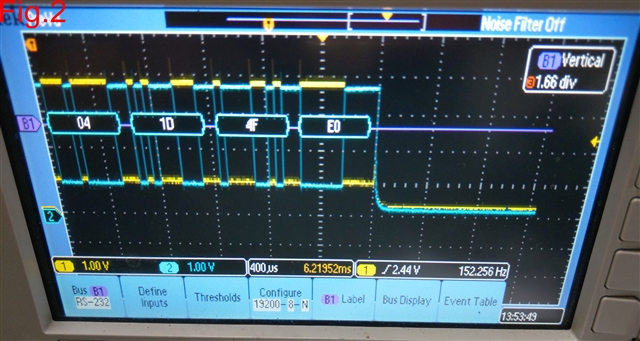

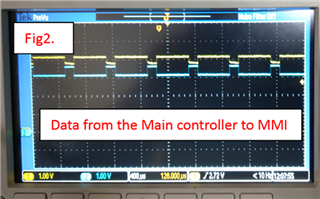

The failure mode happened on the main control board is that the 485 IC can receive the data correctly, but the driver function is abnormal. No data or abnormal data(Fig.2) is on the RS485 bus when the IC is at driver mode. We think the RS485 ICs on the main controller are failed actually. Those curves are DA to DCG, DB to DCG.

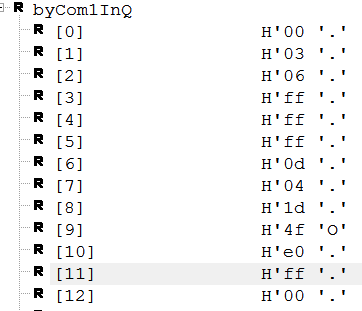

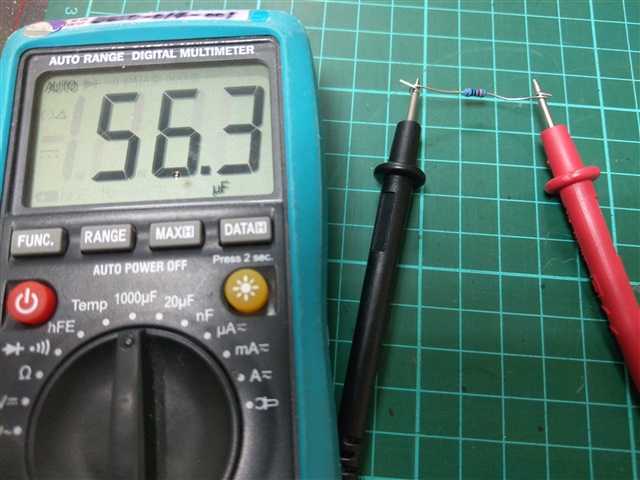

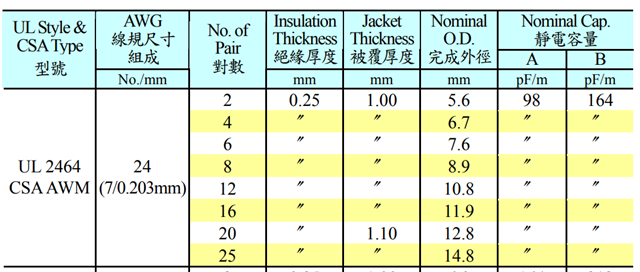

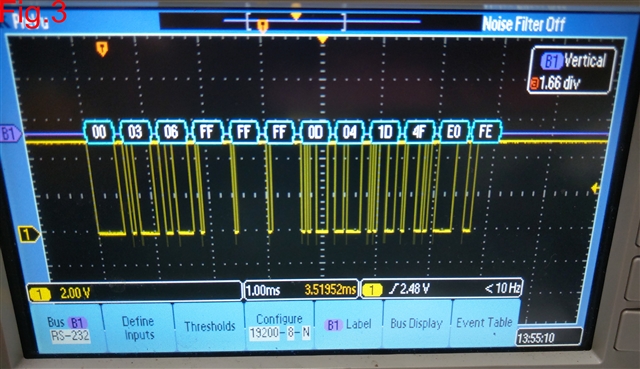

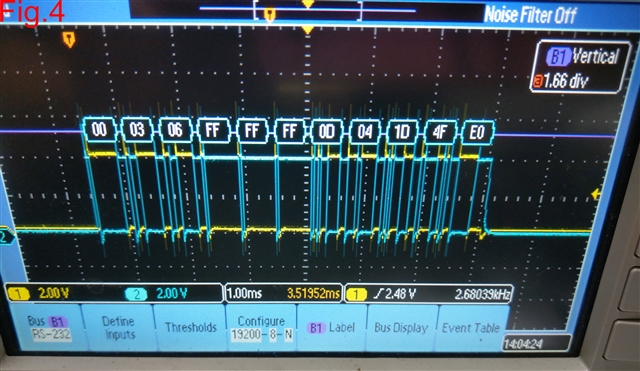

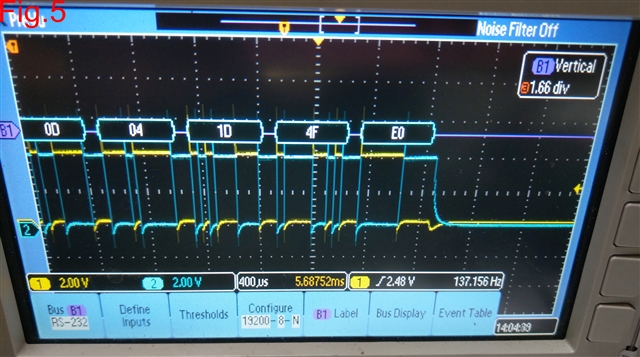

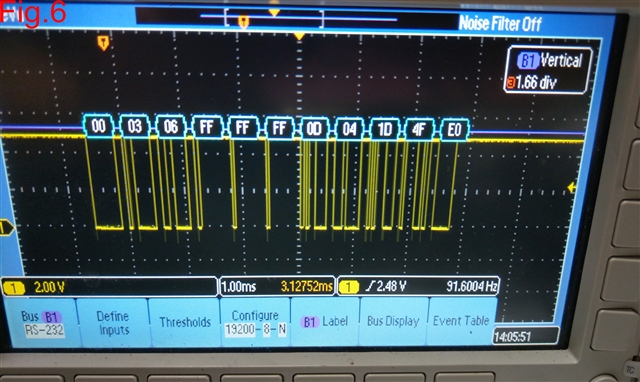

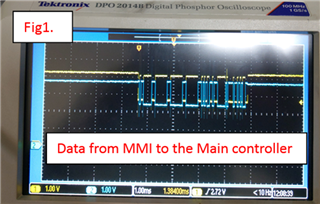

The failure mode happened on the MMI controller is that the MMI controller can not receive the data correctly. We find the MMI controller can receive data, but there is one byte(0xFF) more or one byte less at the end. For example, the correct count is 207 bytes, but the MMI controller will receive 206 or 208 bytes. When we remove the terminal resistor (120 ohm), the MMI controller can receive the data correctly. The distance between two controller is about 1.5m. Now our one question is that why the resistor affects the receive function on the MMI controller? Is the RS485 IC on the MMI normally?