Other Parts Discussed in Thread: TUSB216I

Hi

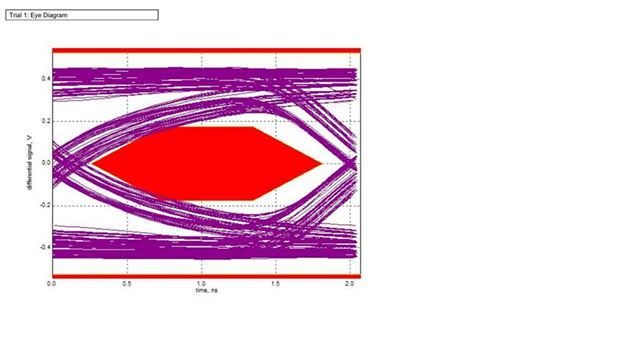

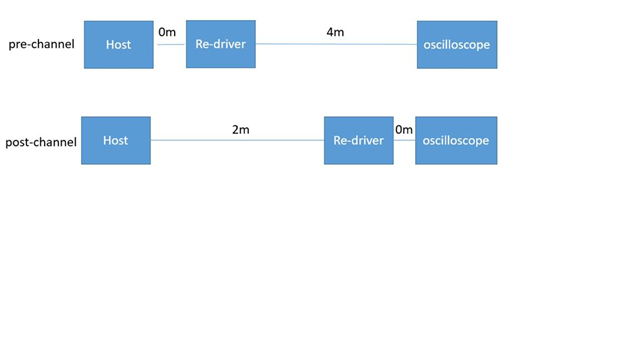

Since there is no eye diagram data of the first 5 meters of the channel in the TUSB213 specification,

can I confirm the actual situation with you? Supports up to 5m pre-channel or 2m post-channel cable length The first 5 meters of the TES test channel → result: Fail