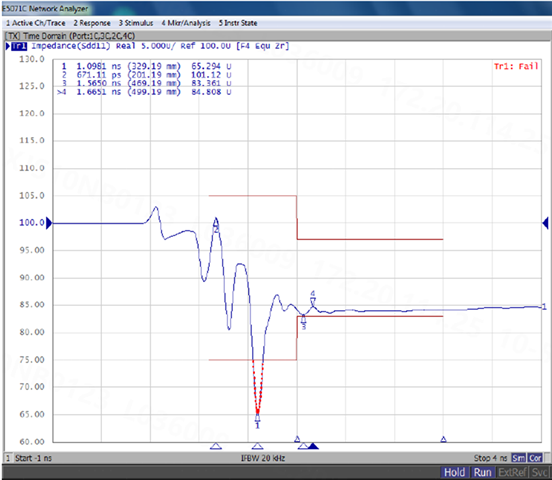

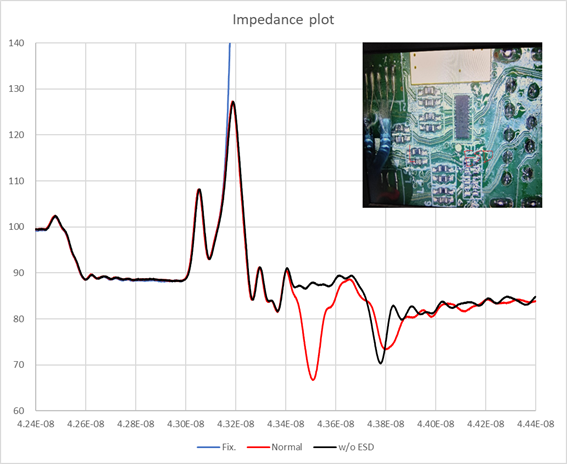

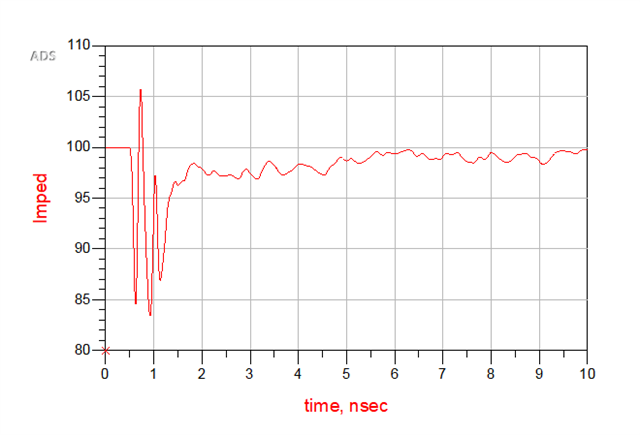

Customer feedback that the USB3.0 requirements cannot be met when using this product。

Do we have the related SI mode of high speed test?

Or any other experiment results?

Which could convince customers that this is not our device's problem.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.