Hello,

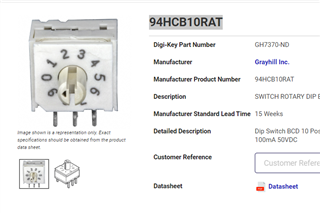

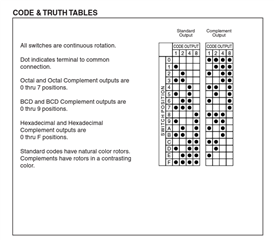

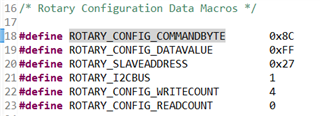

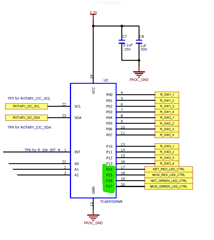

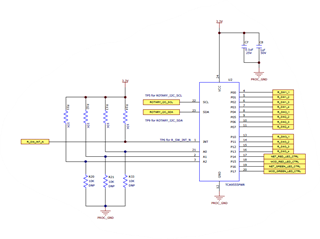

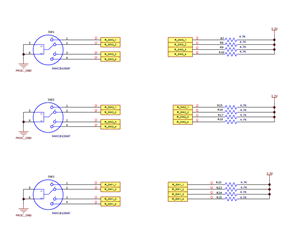

Below is the schematic where IO Expander connected with Rotary switch.

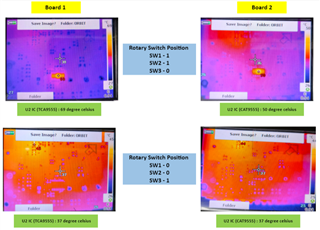

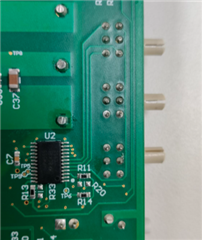

IC is just placed bottom side of PCB board.

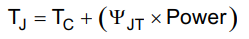

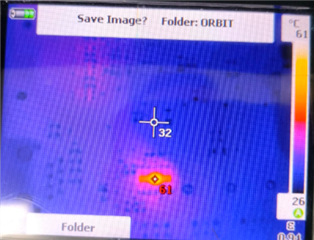

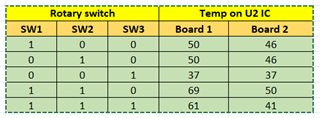

Initially, all rotary switches were on 0's position and temperature was 28 degree C on IC body(Measured by Multimeter). When we changed the setting of rotary switch positions from 0 to 1 then temperature was increasing approx. 10 degree on each changes. W changed the rotary switch position one by one.

When all rotary switches are on 1's position then Temperature was 49 degree C on IC body.

Is this temperature changes bit concern for IC and IC functionality?

Please share your comments and suggestions.

Best regards,

Kiranjit