hello

can you please advise the points below. the first 2 are info on signal customer didn't find in datasheet. the rest are timing that may require clarification:

- RGMII RX[3:0]: Vout_H and Vout_L

TX[3:0]: Vin_H and Vin_L

- MDI output common mode voltage: Vout_H and Vout_L

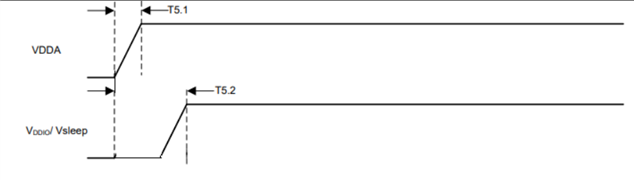

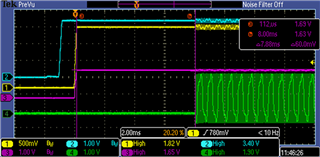

- How to understand T5.2? what is the delay offset for all supplies?

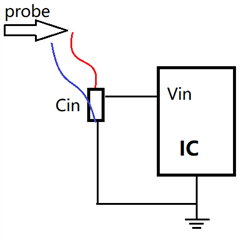

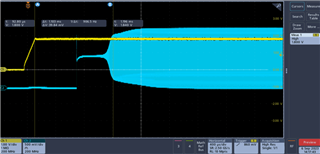

- How to capture T5.6? Is there a sign or mark that shows strap latch-in occurs? I want to measure T5.6

- T5.7 means which CLKOUT for DP83TC813R?

- Is there a sign or mark for idle stream start-up? Can I capture the sign or mark to measure T5.6?