Other Parts Discussed in Thread: TCA5405, SN74LV8153, TSU6111A, TCAL9539-Q1

Hey Interface team,

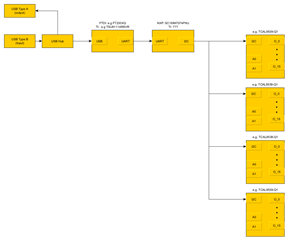

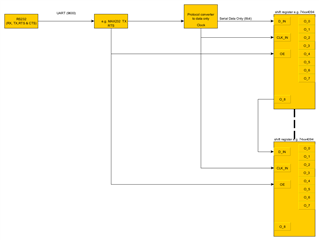

I have a customer working on a project and we were hoping to get your advice on possible solutions to a design challenge we are running into. Here is a summary of the application along with a block diagram to better visualize the system:

Customer design challenge: We're looking for a solution that receives 40-bit UART (RS232) stream and put this to 40 dedicated outputs. Current idea is to use a TI MAX232 to get TTL-signaling and then put this stream into a serial shift register like 74xx4096 device. The current problem is to get rid of the protocol bits like start, stop and parity bits, as well a generate a clock signal out of the UART stream. Is there a device which can do that? The solution shall use devices without any programming, strapping is OK. The 74xxx4096 should drive a low ESR FET; therefore a 5V surrounding would be great, but a 3.3V plus level shifter would be also OK.

At first glace, I figured an MCU may be needed to generate the appropriate data bits and clock signal but I figured it was worth running by your team to see if you know of any solutions that can do this bit stream manipulation in HW without the need for coding or programing.

Please let me know if you need any further clarification or have any follow-up questions!

Best regards,

Matt Calvo