Dear Team,

Greetings in advance!

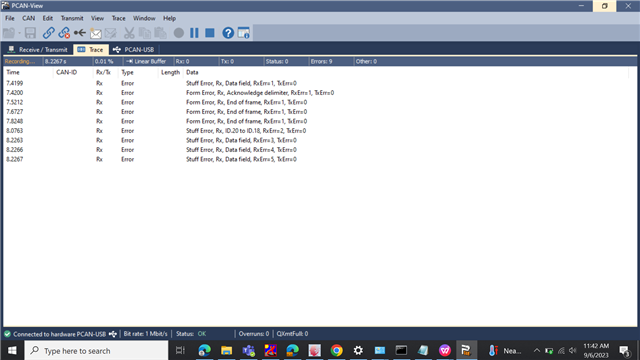

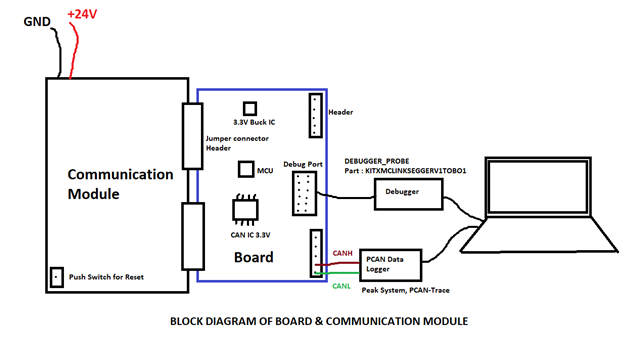

We have made a CAN circuit with CAN IC part number (SN65HVD230QDRG4Q1) & Controller we are using MCU Part number : XMC4108Q48K64BAXUMA1, But we are trying to fetch the data through PEAK System P-CAN Trace Data logger but we are unable to fetch the data, It showing some errors instead of showing Tx & Rx data. Some times it is unable to show anything. I have attached the error list for your reference. Note: We have Qty: 05 Nos. Identical PCB boards out of 05 board only one board is working fine but other boards are unable to fetch the data, We are keeping same (Same Firmware, already Checked other boards components including resistors & capacitors that are found OK, same setting for PEAK System P-CAN Trace Data logger). So, Team you are requested to suggest for any solutions for the same.