Hi Team,

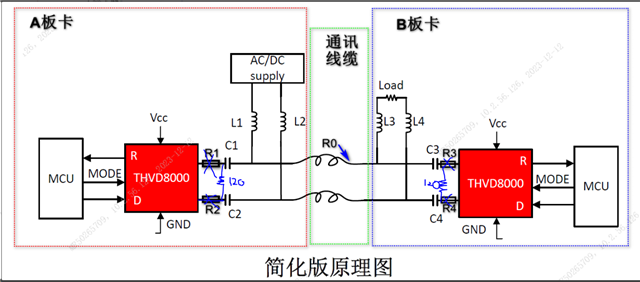

Customer design THVD8000 system like below, where R1=R2=R3=R4=200hm, C1=C2=C3=C4=470nF, L1=L2=L3=L4=10uH. Cable resistance R0=1.9ohm. Carrier frequency is 5MHz. The detailed schematics I will attach later.

For A board, we got four boards: A1, A2, A3 and A4. When these boards communicate with B board, A1 always success, A2 always fail. others sometimes success. We exchange the chips on A1 and A2 and found that A2 becomes success and A1 become fail. And then we tested the carrier waveform and RX waveform and found that the reflection of the failed one take times to die down which cause the ripples (the right picture). And we are suspecting that's the reason why the communication fail. The left picture is the good waveform for the successful communication.

So the questions are:

1. with same design, why these devices behave different?

2. In THVD8000 design guide, termination resistor can help to settle down the signal quickly. Do you have a guide for how to select the resistance value of termination resistor?

3. If choose a fixed termination resistor, how to guarantee 100% successful communication in production?

Thanks!

Rayna