Tool/software:

Hi, Support Team

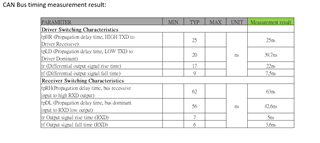

our client use TCAN330 and test CAN Bus timing measurment result as below chart:

about test result have any concern?

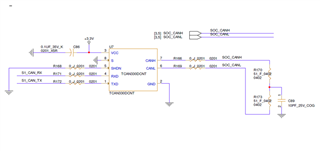

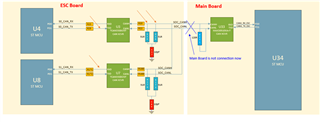

schematic:

if any suggestion, Please advise me.

Thanks,

Best regards,

Lawrence

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Hi, Support Team

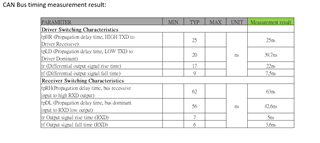

our client use TCAN330 and test CAN Bus timing measurment result as below chart:

about test result have any concern?

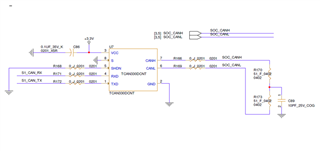

schematic:

if any suggestion, Please advise me.

Thanks,

Best regards,

Lawrence

Hi Lawrence,

I don't have concerns on the test results of propagation delay. If customer has concern to verify datasheet values with unit performance, we would recommend to measure the loop delays as these are better defined in the datasheet and more applicable to system behavior.

Regarding the schematic, CAN requires 60 Ohms bus termination, so usually customer will place 120 Ohms on each end. Please make sure the termination value is correct. For the capacitance the common range will be 4.7nF to 100nF. This capacitor is meant to work the split termination resistors configuration be low-pass filters for both CANH and CANL. I would also recommend to place common mode choke, bus filters and TVS diode for better EMC performance, if necessary.

Regards,

Sean

Lawrence,

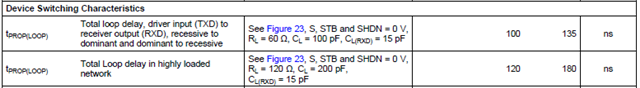

Please make note of the test conditions in the Switching parameters table when testing the transceiver timing. There needs to be 60 ohms termination and 100pF differential capacitance between CANH and CANL. In your circuit I see only 120 ohms termination and no load capactiance.

That being said, I'm not concerned with the timing values you have measured, but please try again with the correct loading conditions.

Regards,

Eric Hackett

Hi, Support Team

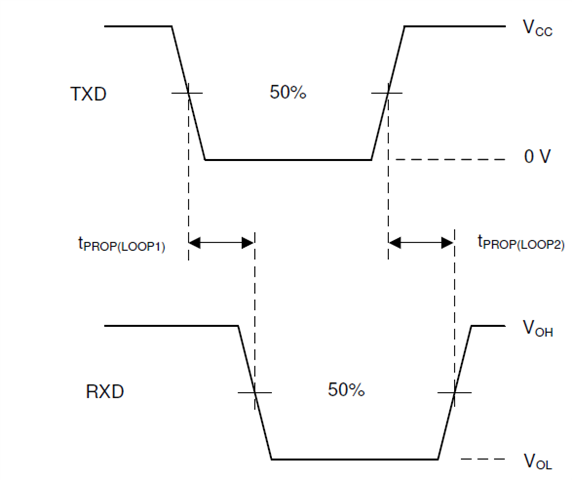

here is our clinet measurment diagram as below chart:

if any, Please advise me.

Thanks,

Best regards,

Lawrence

Dear all,

We measure all timing in system circuit, and it will be operated in actual situation.

So we need to judge the testing result is pass or fail.

Hi Lawrence,

The test results have no issue, however as Eric said, their testing conditions are different with the specification in datasheet.

If possible, use the data sheet test condition (60Ohms, 100pF) and measure the loop delays to see if within the range.

Regards,

Sean

Hi Mulder,

The rise and fall time was measuring the time it takes for the differential voltage to transition from 10% to 90% of its final dominant value. This was done on a simulated differential bus load of 60 Ohms and 100pF. No cabling, secondary transceivers, or other external loads were added. Because the test condition you described includes a different bus termination and load capacitance, the measured values are expected to be different from the typical values in datasheet. So we asked to measure these characteristics again with the setup I said above, if the purpose is to to verify datasheet values.

As we do not specify maximum values for these characteristics in the datasheet, it is difficult to say a pass/fail value. But even the test conditions were different, I don't see a significant deviation from the typical value in datasheet so I don't have concerns with the measurement results. In addition, I would recommend to measure the loop delays, as these are better defined in the datasheet with max value.

.

.

Regards,

Sean

Hi Mulder,

Yes the probe location is correct. Ensure the bus loads match the datasheet test condition.

Regards,

Sean

Hi Mulder,

Thanks for your sharing. The test results are good.

Regards,

Sean