Other Parts Discussed in Thread: USB2ANY, , DS250DF210,

Tool/software:

Hi,

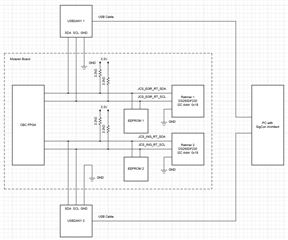

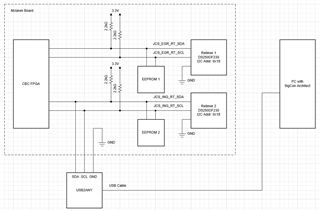

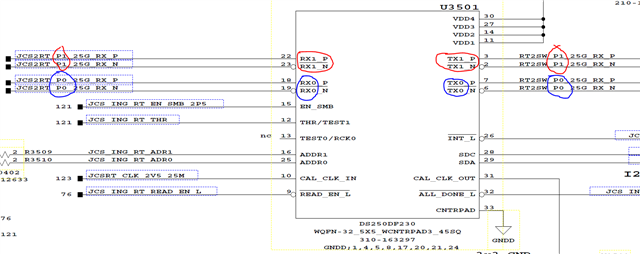

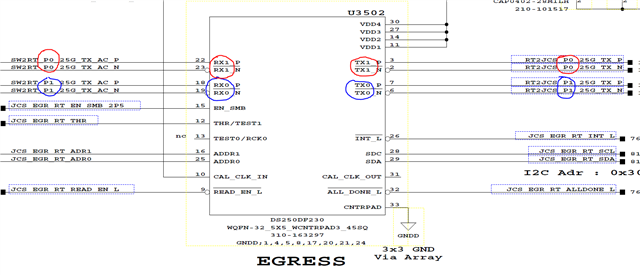

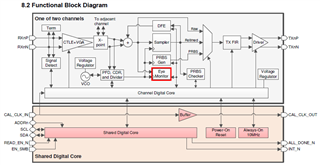

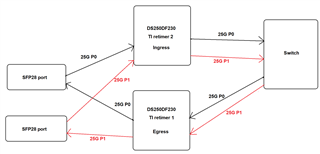

The following snapshot represents the block diagram of the section where TI retimer is used in Mclaren board.

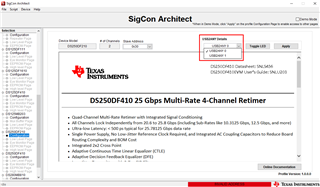

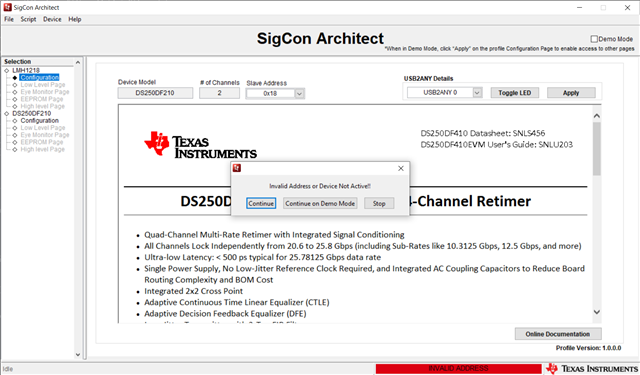

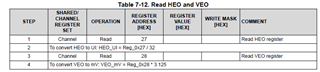

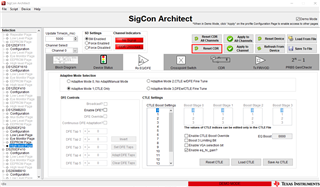

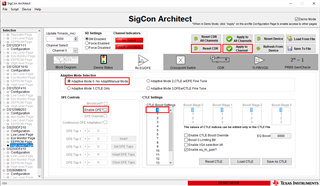

We're planning to use SIGCON GUI (with DS250DF230 updater file) to read/write TX settings, start/stop PRBS, PRBS BER, dump dfe Rx settings, read internal Eye (HEO,VEO) etc. Need help to understand the connection points for USB2ANY device in the Mclaren board.

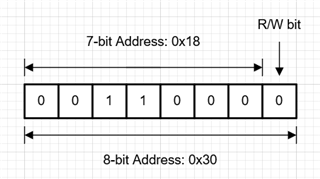

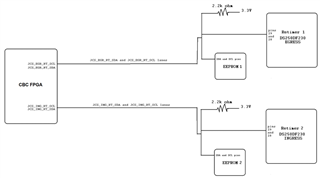

For your reference, adding below the block diagram showing SDA/SCL connections to the two TI retimer devices DS250DF230 in Mclaren board.

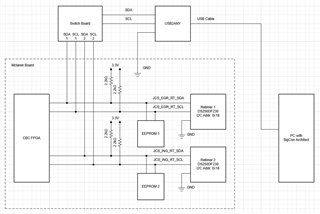

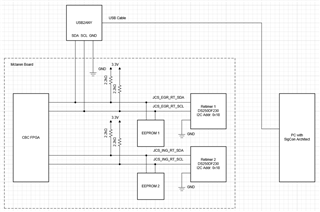

I got an idea from our my colleague who used SIGCON tool before for another project, and I have created one diagram (see below). But if this is correct, I want to know how can we probe the wires at TI retimer SDA/SCL/GND pins in Mclaren board. Because those pins are already connected to other two devices as shown in the above snapshot. It would be helpful if you can update the above block diagram with the changes required for connecting TI retimer to USB2ANY device.

Please let me know if you need any further information.

Regards

Vimal Vivek