Tool/software:

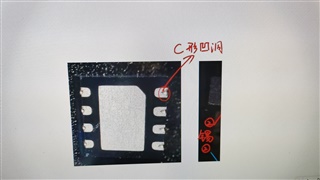

Could you tell us the standard or recommended with welding spec of the bottom pin with C-groove hole of this IC, thanks.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Could you tell us the standard or recommended with welding spec of the bottom pin with C-groove hole of this IC, thanks.

Hi Eric,

we want to know the soldering spec for the C-groove hole, Is the depth filling for the C-groove hole must be100%? could you tell us the spec, thanks.

Carol,

There is not a minimum percentage requirement for establishing an electrical connection, however, the purpose of these wettable flanks/notches in the package are to enhance the effectiveness of automated optical inspection devices when evaluating solder joints. Without these notches, it can be difficult for poor or missing solder joints to be detected during optical inspection. To fix this, the groove you highlighted allows the inspection process to determine whether solder is present by checking to see whether the groove is visible. If visible, it could be an indication that the solder connection is not reliable.

Though not the exact same package, there is a document that might help give even more context about soldering these types of packages. See here: https://www.ti.com/lit/an/slta069c/slta069c.pdf

Best,

Danny