Tool/software:

Hi

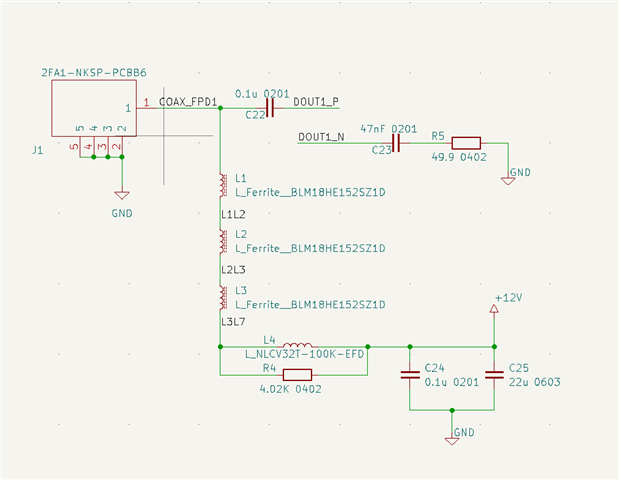

We have noticed excessive heating on the ferrite beads in our POC network, to the point where one of them has burned.

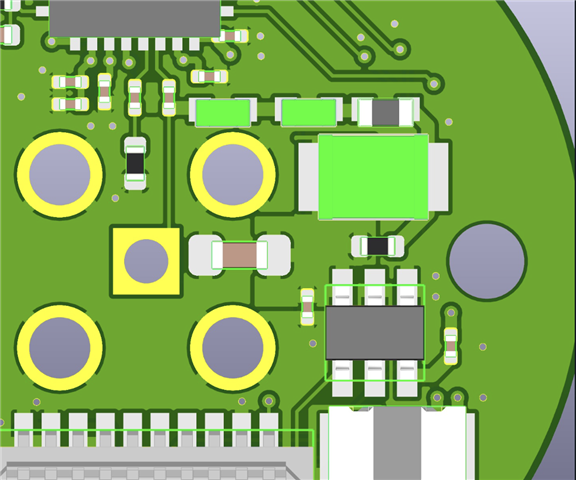

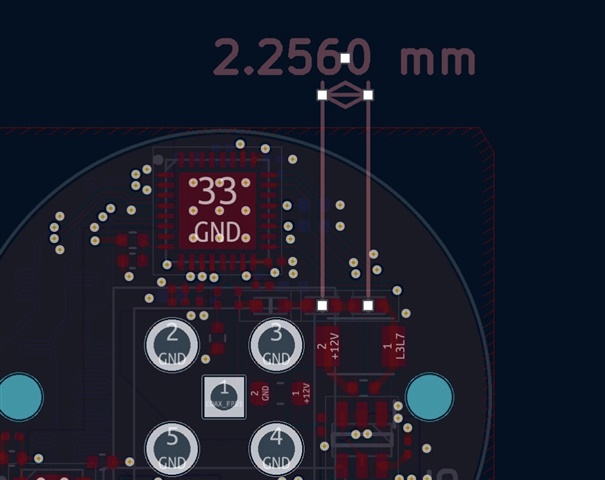

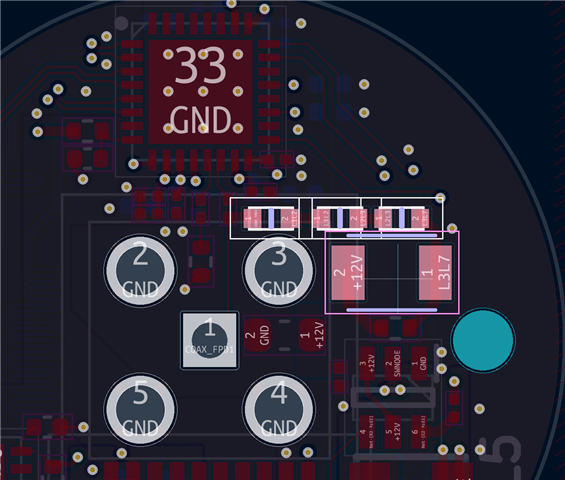

Please see the relevant schematic and layout section below:

There is a related bug from 2015 that did not get any response, but the symptoms seem quite similar. Our module is using 80mA which seems much below the spec of the ferrite bead.

Please let me know if I can share any other images/collateral.