Tool/software:

Hi All,

Happy new Year!

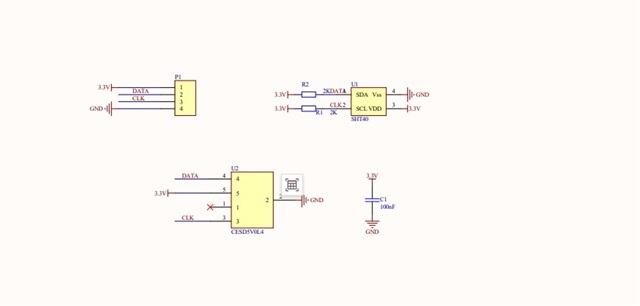

Due to the previous generation IC‘ EOL, the new one with ESD immunity downgrade from HBM 4Kv, MM 200v , CDM 750V/500V to ESD HBM 2Kv, CDM 500V.

After using the new one, we encountered device failure after assembly process.

in order to solve this issue, we chose ESD protection IC, the situation has improved, but not completely solved.

the SCH as following

the PN of ESD is CESD5V0L4

let me explain our assembly process in detail

Wrapped in epoxy resin glue PCBA--1, through the ABS material tube-2, in the process there will be a chip on PCB damage, would you please help to recommend a TI suitable ESD chip can be as far as possible to solve this issue?

Many thanks

BR

Kelly