Other Parts Discussed in Thread: STRIKE, TDP2004

Tool/software:

I am going to use TMDS1204 for my project and saw a recommendation in the datasheet for using serial resistors on the hi-speed lanes as additional protection related with ESD TVS diodes.

Let me introduce my understanding please let me know if i miss something:

a. Any additional serial components on the hi-speed traces are sources of unmatched impedance and kind of source of reflection, which should increase return losses and insertion losses.

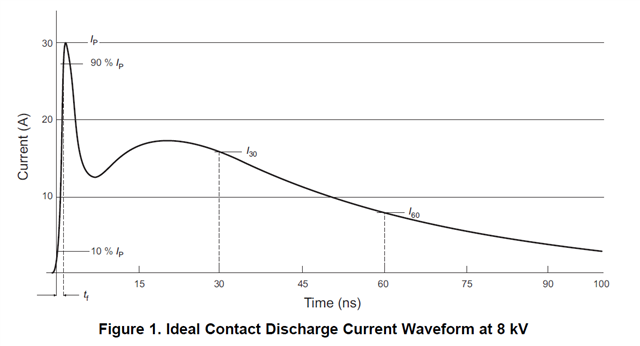

b. More popular level of ESD protection is IEC 61000-4-2, level 4. 15kV/8kV

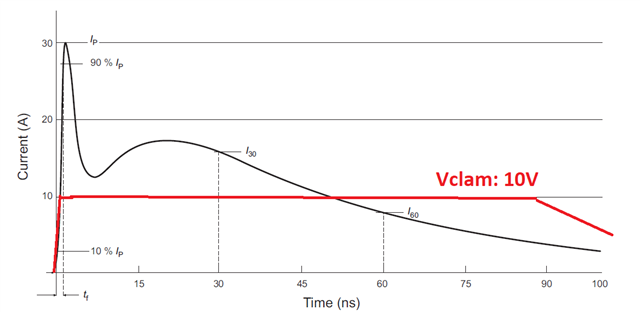

During the ESD event even with ESD TVS diodes, there will be some overvoltage impulse as mentioned in the datasheet "A clamp voltage greater than 4.3V will require a RESD on each high-speed differential pin."

Based on my understanding TVS diodes cut the initial ESD impulse down to Vclamp (Vsnapback) and since the voltage source (ESD) is still the same than a duration of the overvoltage impulse (after TVS) sould be the same as the duration of the ESD initial impulse.

c. TMDS1204 has its own ESD protection "Human-body model (HBM)" up to 4kV, as I remember HBM model has a similar time domain of the ESD events, and since point "b", looks like internal ESD HBM protection should be enough for protect by Vclamp (Vsnapback)

So let me ask:

1. Do you have any estimation of how serial resistors (0402) affect the hi-speed signal integrity?

2. Could you please clarify the benefits of using serial resistors here?

3. There are in the datasheet:

"It is recommended that the ESD protection component has a breakdown voltage of ≥4.5V and a clampvoltage of ≤4.3V. A clamp voltage greater than 4.3V will require a RESD on each high-speed differential pin."

and the recommendation to use PUSB3FR4.

The last one is a snapback device, and as I can see that has Vclamp 4V (for 7A) and Vbreakdown 9V (typ).

Is my understanding correct that using PUSB3FR4 excludes the need to use ESD serial resistors?

Thank you!