Tool/software:

Thank you for your help.

I'm in trouble.

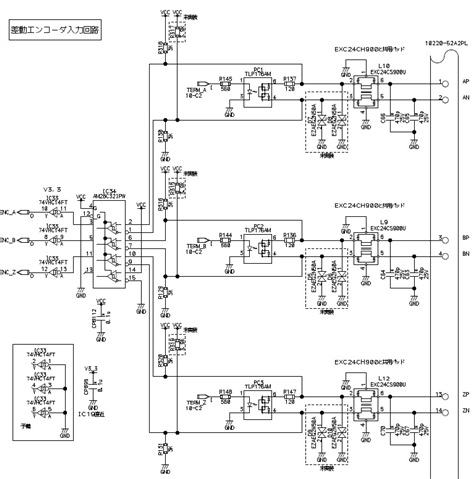

I have developed a control device for a two-phase stepping motor.

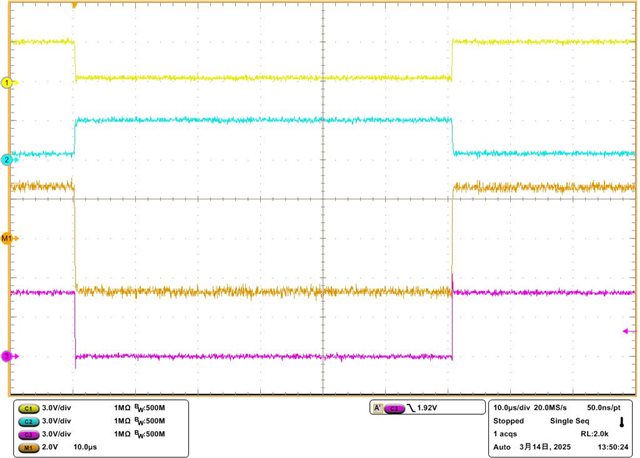

The two-phase stepping motor has an A/B phase output encoder (RS422 driver output).

The output of that encoder is input to the control device I developed.

I am using a line receiver: AM26C32IPW for the input part.

However, it has broken down over time.

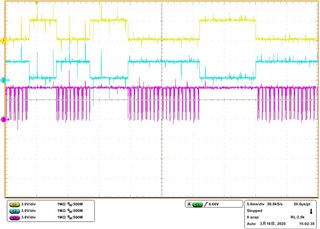

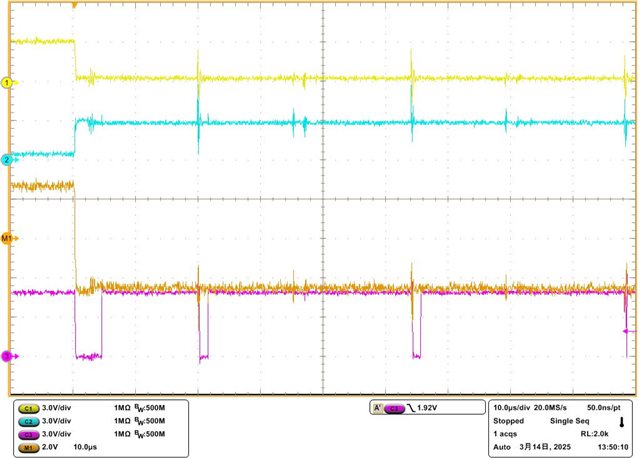

The output of the differential input result is abnormal.

I have not been able to identify the cause.

When I removed the broken AM26C32IPW from the board and examined it, I found that the impedance of only one of the input terminals was abnormally small.

The table below shows the results of measuring the impedance between VCC and the input terminal, and between GND and the input terminal.

Pin Signal VCC GND

-------------------------------------------------------------------------------

1A Phase A + 252kΩ 3.2MΩ

1B Phase A - 3.2MΩ 250kΩ

2A Phase B + 252kΩ 3.2MΩ

2B Phase B - 2.9MΩ 0.57kΩ

3A Phase Z + 252kΩ 3.2MΩ

3B Phase Z - 3 2MΩ 252kΩ

4A Unused - -

4B Unused - -

-------------------------------------------------------------------------------

Only the impedance between the pin 2B and GND is low (0.57kΩ).

This failure occurs in multiple devices.

However, it occurs randomly in phases A, B, and Z.

What do you think is the cause of this failure mode?

Thank you in advance.