Tool/software:

Hi,

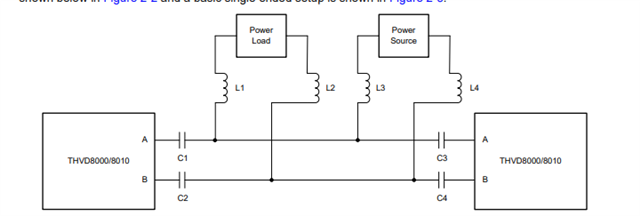

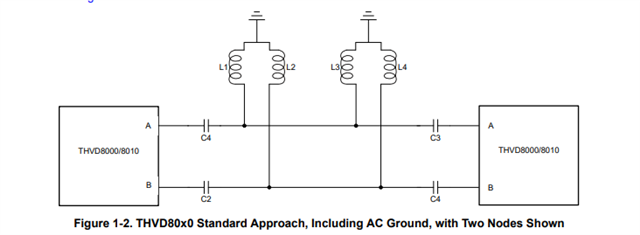

I have a multi-node setup where each node will pull power off of the power line and power their MCU using a buck converter.

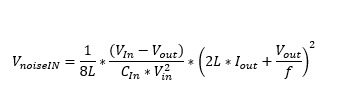

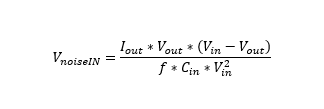

My Fset frequency is 500Khz and I am planning to use a buck converter that switches at 400kHz.

Will this cause issues to my communication? Will selecting buck converter with a higher switching frequency such as 1.1Mhz be a better choice?

Also, if I have long cable run and the voltage on the line varies due to dynamic loads of all the nodes, will that cause issues with communication?