Tool/software:

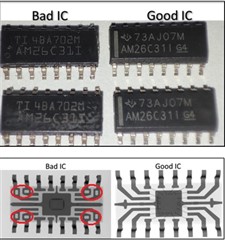

Factory has encountered a high fallout at production after supplier cut in the new die (see x-ray) chip.

So please answer to the highlighted Bold questions in the below summary.

|

Pin |

Pin Description |

Remark |

|

7 |

GP_SYNC |

Test verify signal is 3.95V±1.55V; pulse width 1.028 ±1% |

|

9 |

GP_DATA_TX |

Test verify DATA transmit out and receive. |

|

10 |

GP_OUT+ |

Test verify signal is 125kHz ±10%; with 50% ± duty cycle; with amplitude 3.95V±1.55V |

|

15 |

GP_CLK |

Test verify signal is 250kHz ±10%; with 50% ± duty cycle; with amplitude 3.95V±1.55V |

U14 (AM26C31I) on the board convert single ended signal GP_DATA_TX to positive differential signal (GP_OUT+, pin 10) and negative differential signal (GP_OUT-, pin 11).

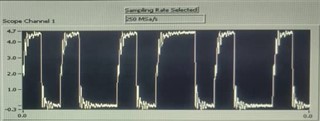

- A sub-test is executed to measure the differential DATA (125kHz), duty cycle (50%) and amplitude (2.4-5.5V) for GP_OUT+ signal. See modular oscilloscope signal captured by tester.

- Failures are mainly related to clock (~260kHz) and duty cycle (97.7%).

- Each of the differential output has a series resistance 40 ohms. The sub-test pass when the series resistor value reduced (33 ohms – 36 ohms). There is an indication of the new die AM26C31IDR differential output impedance had changed but PCN claimed no form, fit and function affected. The failed board is reworked with old die (with suffix G4) and it able to pass the sub-test. Could TI provide the output impedance for both old (AM26C31ID, AM26C31IDG4, AM26C31IDRG4) and new die part (AM26C31IDR) ?

- The lead frame (example pin 1,2,7,8,9,10,15,16), internal team has a question whether the out impedance is still identical between the old part and new part?