Tool/software:

Dear TI Representative

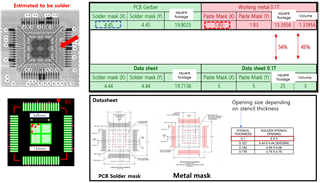

We have examined the DP83867IR_1G Ethernet transceiver mounted on our produced boards using X-RAY, and we observed a phenomenon that appears to be insufficient solder.

Comparing the metal mask stencil area manufactured by our SMT supplier with the TI Data Sheet, we found that the solder volume is approximately 45% of the Data Sheet specification.

Therefore, we would like to ask the following questions:

1. Do you assess that a solder volume of 45% compared to the Data Sheet specification is acceptable and does not cause any issues?

2. Up to what percentage of solder volume compared to the Data Sheet specification can be considered acceptable without causing problems?

3. Does a solder volume of 45% compared to the Data Sheet specification result in performance degradation due to heat generated by the component?

Thank you