Other Parts Discussed in Thread: THS6222

Tool/software:

Hi Team,

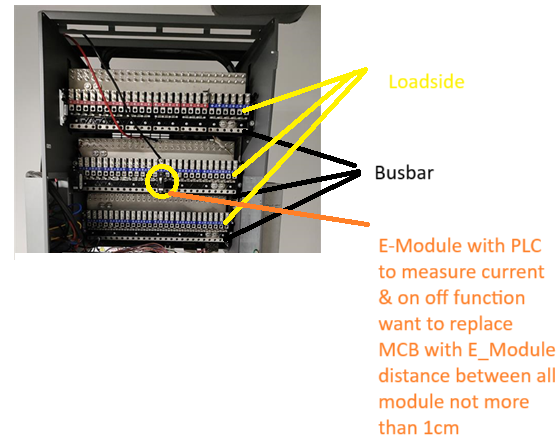

We want to design Power line communication system for DC rectifier. Our system voltage will be from 48V to 60V. with module of ~100. Can we develop by Using THVD8000 IC bus.

will this support addressing of ~100 Modules? Can you please help here. Our agenda to read the Current going through 48-60V bus for each load and can be control its power on off.

This system will communicate on powerline to main module of each load.

Kindly suggest basic micro controller as well to drive THVD with one ADC to read current & 1 GPIO to control on off action.

Thanks for understanding.

Regards,

Ashutosh