Tool/software:

Hello Expert,

May I check an application scenario with you?

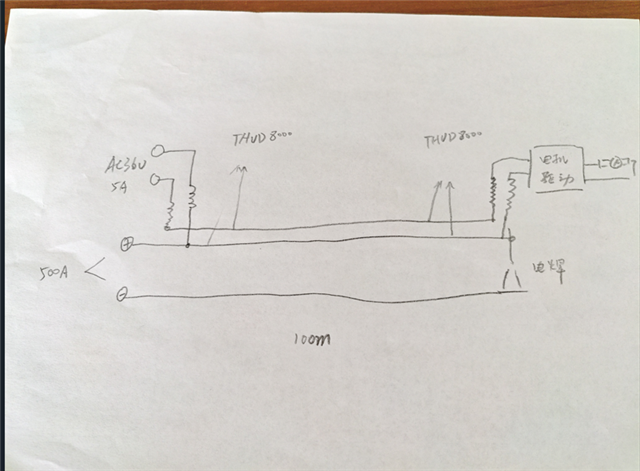

This is the scenario I planned for carrier transmission 100 m with low voltage carrier Two wires are 36 V AC sine wave for motor drive board power supply, one of which shares a single cable cross-sectional area of the welded loop 50 mm2 The average current of the welded loop is 500 A maximum. the current will fluctuate, typically within 100 volts, Please help me analyze if our chip can achieve, and if we can achieve carrier frequency, you can probably get how much

Best regards,

Wenting