hi,

i need to design application based on 5V MCU that need to intreface with CAN bus.

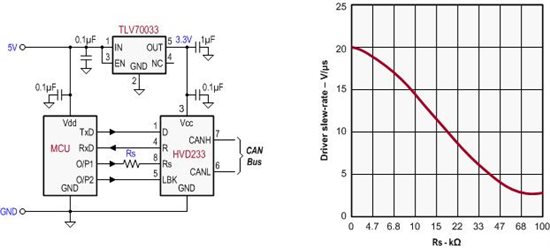

our customer uses SN65HVD233 to implement the CAN bus.

I need CAN bridge that can tolerate 5V supply and 5V UART connection to the MCU, and ofcuorse can connect to the SN65HVD233.

please reccomend a CAN component to implement.

please send me a reference design for the CAN bus component.