Hi all!

I'm testing ethercat communication in a custom board (broad cut&paste from ICE demo board). Everything is fine, except for frequent RX error at physical TLK110.

Ethercat diagnostic tools report "frame lost" increasing count.

I've tried these:

- decrease distance between PHY and MAGNETIC (less than 5mm)

- change terminating resistors values ( slightly less and more than 50Ohm)

- increase bypass capacitors value

- change magnetic type and manufacturer

- change Ethercat master

I can't see any valuable difference in data error rate.

I've double checked resistor values, clock signals, pull up/down, with no result.

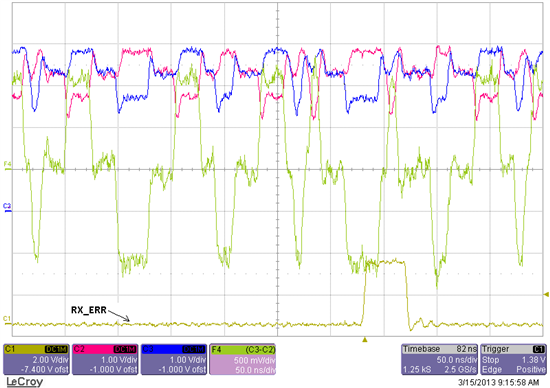

Here you can see a oscilloscope dump when an RX error occurs:

RX_ERR in channel 1 is pin 41 output signal. Channel 2 and 3 are RX+ and RX- signals. Trace F4 is the difference between RX+ and RX-

Differential signal seems fine to me.

This problem is going to be a BIG issue. Any suggestions?