Dear team:

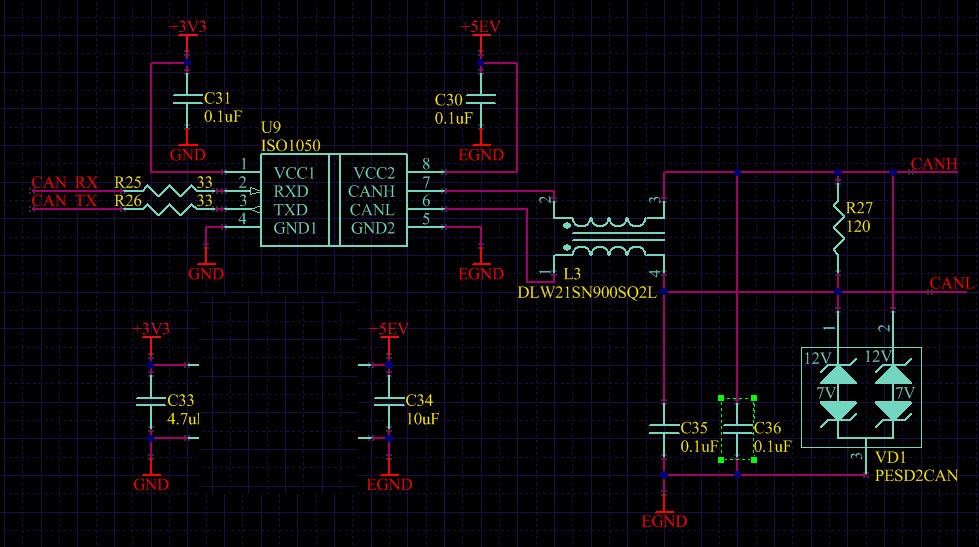

Due to board size limitations, small-size transient suppression diodes are required. Do not know how to choose. Under the guidance of trouble.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.