Other Parts Discussed in Thread: SN6505A

Hi,

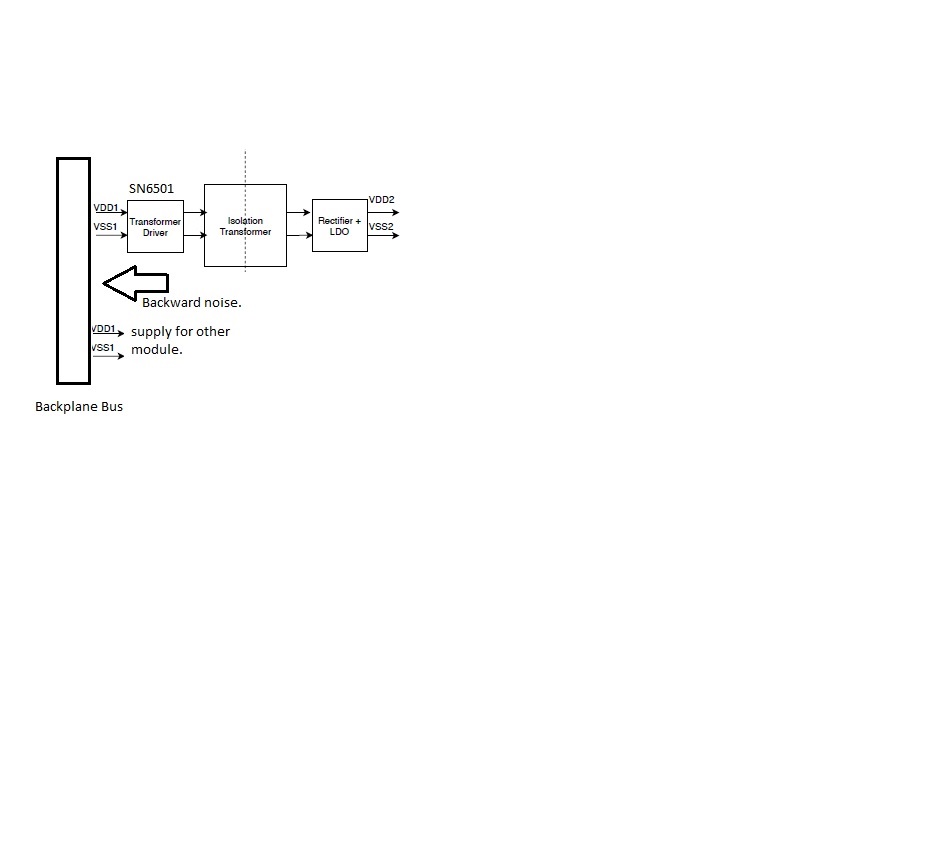

I am using SN6501 for 5V to 5V isolated DC-DC power supply design.

I am using local 5V supply to provide VCC to SN6501. This 5V is output of a separate DC-DC converter. The same local 5V supply is used for other module also.

My question is, When SN6501 operates, due to switching it will throw a conducted EMI noise in this 5V supply lines.

Due to noise on 5V supply the other module may malfunction.

Please suggest solution to this problem.

Regards,

Prasad.