My customer asks:

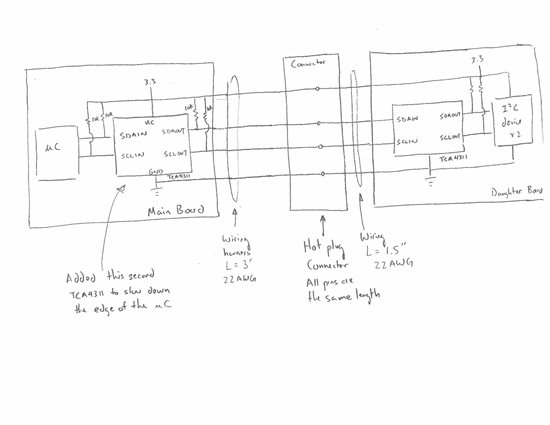

In our application we have our uC driving the I2C bus and this goes off board via a 3’ wiring harness which then goes to a connector that can be hot plugged. On the other side of the connector we plug our daughter board into which has a TCA4311 chip for hot plug of the I2C.

My problem is that the edges that the uC switches the I2C signals is too fast and causes a lot of noise on the daughter board. To slow this edge down, I am thinking about using a second TCA4311 on the main board which acts like a buffer. I have attached a diagram of what I would like to do in this email. From the datasheets of the TCA4311, it shows a application for running long distance I2C by putting two TCA4311 back to back. The part that confuses me is that they have SxxOUT wired to each other.

Also, in my application, I need the hot swap capability and I am not sure if the TCA4311 wired back to back in the datasheet can do that.