Other Parts Discussed in Thread: AM26LV32E, , AM26LV32

Hello,

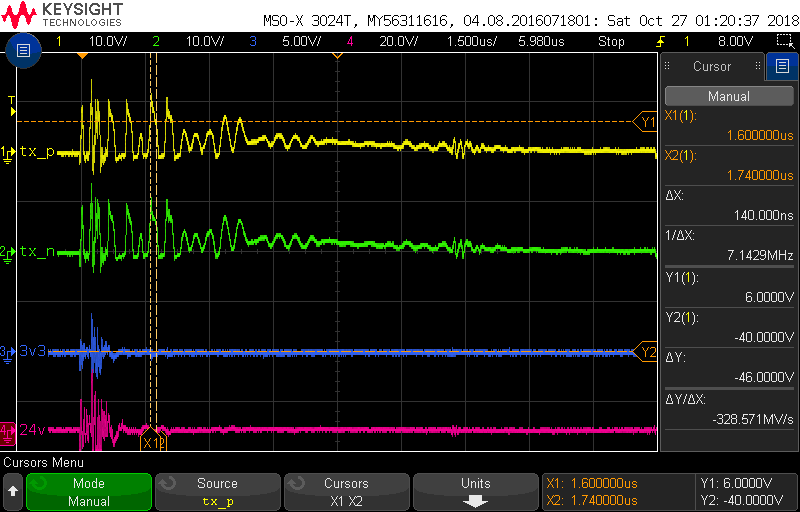

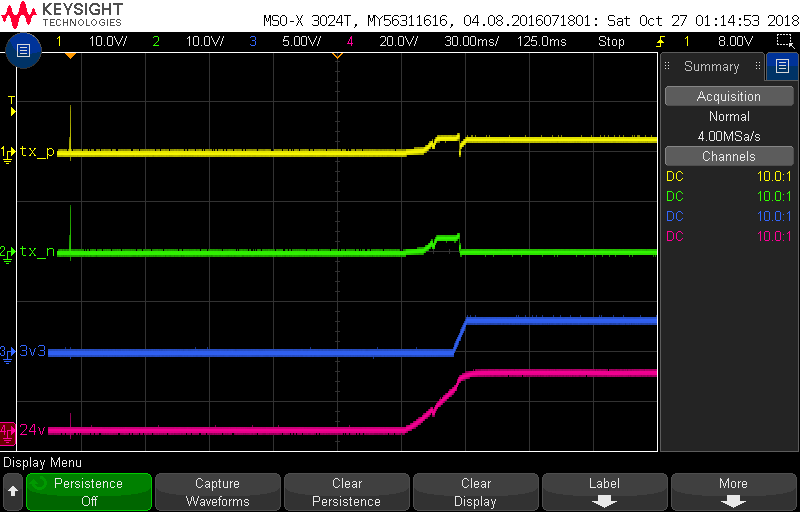

I am troubleshooting a failure in a design where the AM26LV31E driver is not producing a differential signal on the output. The failed leg of the output is a duplicate of the other leg. Both differential outputs are switching, but the outputs are the same. The driver interfaces with a AM26LV32E receiver on another PCB. Both the driver are receiver are running at 3.3V from switching power supplies on each board. The board with the driver is hot swappable in the system, using a hot swap controller that enables its switching power supply. I'm looking for any advice in trying to help isolate this failure mode.

Thank you