Other Parts Discussed in Thread: STRIKE

Dear all

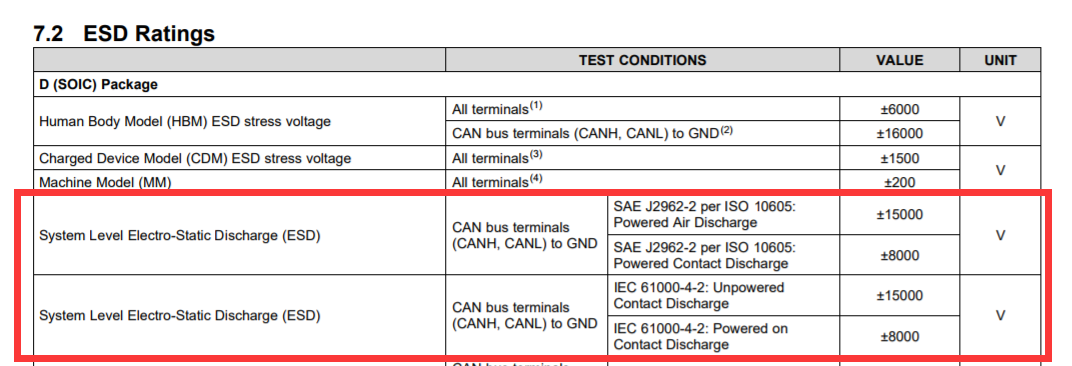

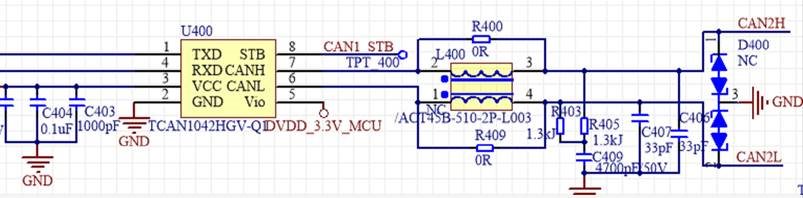

I had test the CANH/CANL pin of TCAN1042HGV-Q1 device with System Level Electro-Static Discharge (ESD), but the device had been damaged.

I want to check SAE J2962-2 per ISO 10605 and IEC 61000-4-2 of datasheet are same to my test equipment.

Please give me the SAE J2962-2 per ISO 10605 and IEC 61000-4-2 source file, thanks a lot.