Part Number: SN65HVD72

Hi

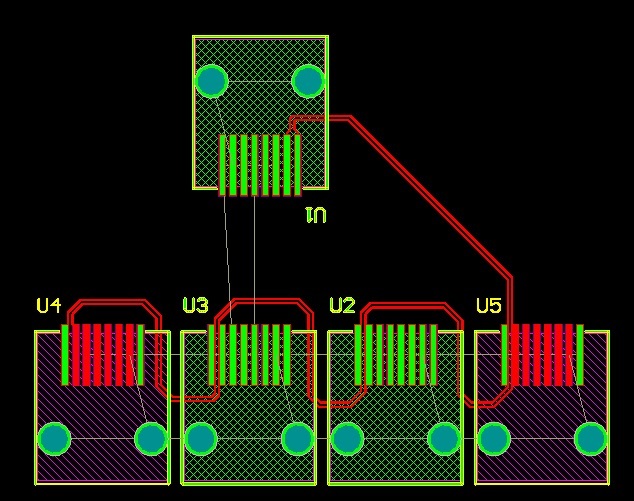

Currently i am using SN65HVD72 for my communication over two boards using UART(baud rate 9600). Both my Primary PCB and Sensors PCBS use a SN65HVD72,

i would now like to connect multiple sensor PCB's to my Primary PCB. Ideally there will be between 2 to 4 sensors.

I believe for this I would need to make a HUB or Switch PCB , where each sensor would be selected one at a time.

How must i configure to use multiple SN65HVD72? Is there a specific PCB layout? Can i use one UART port for the SN65HVD72 devices?