Other Parts Discussed in Thread: MSP430FR2433, BQ25713, TPS5450, EV2400, TPS65987

Hi,

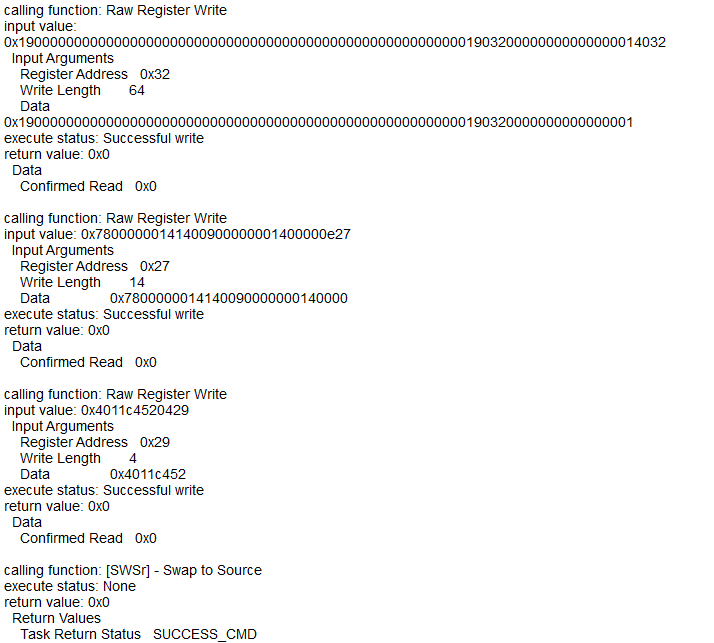

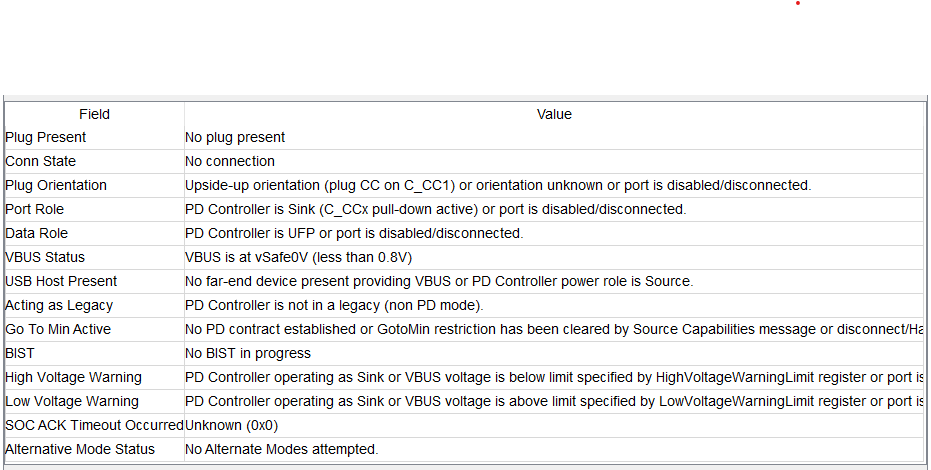

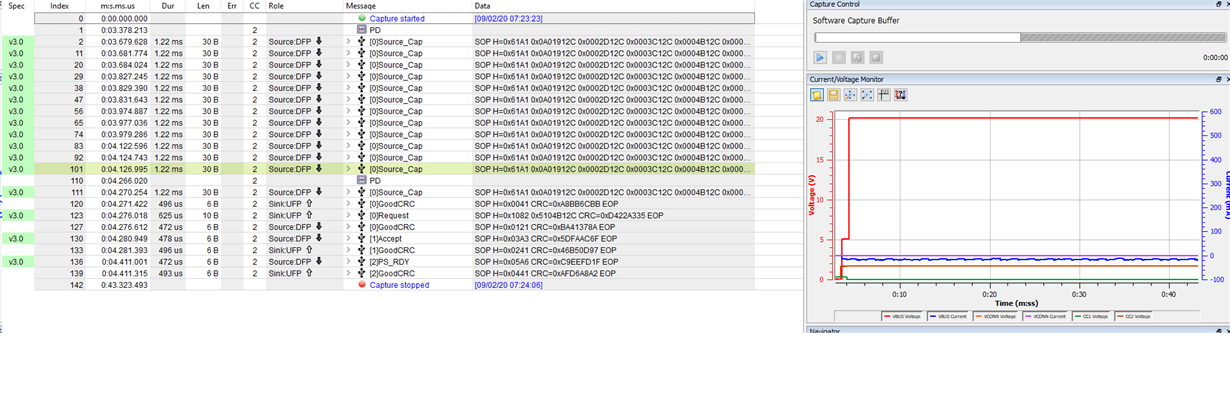

I need to switch a port that is mostly a battery charge sink to a source so that we can use OTG type devices. I've played around with number of settings and registers but can't seem to get it to switch over. Can someone summarize the steps and registers required?

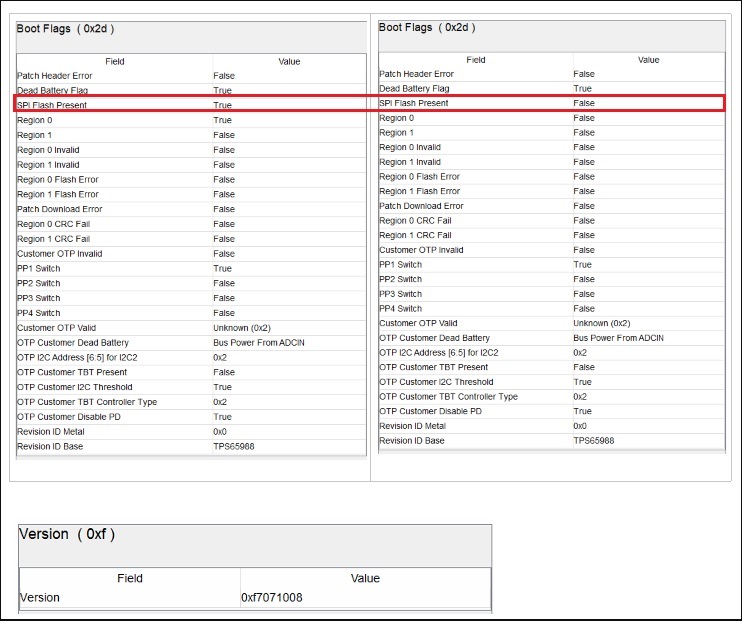

I am starting from the default sink project available in the GUI tool. I setup the transmit source capabilities and asked it to switch over a few different ways.

5V power is connected on PP_HV1 and 2 and 3.3V is powered from an external LDO.

Thanks,

Chris