Hi Team,

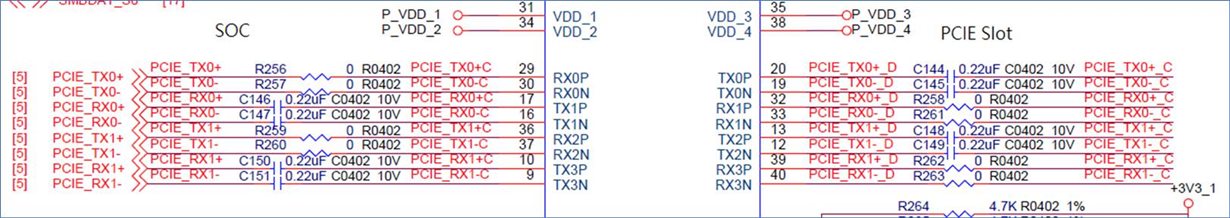

My customer design DR160PR410 for PCIe[x4] application and found "device no detect" issue. The failure rate is 10pcb/60pcs, engineer found it might related to SMT process issue since he re-mount devices again on 4 FA boards then can fix these boards. He will try it on the other FA boards to see if all of them have same problem.

Engineer did some measurement on FA and good boards and the result as following.

The left picture shows the good PCB's result, the signal level of TX side is about 0.7V.

The right picture shows the FA PCB's result, red frame shows abnormal signal level of 1.2V.

1. Customer would like to know what kind of SMT failure can cause this failure phenomenon?

2. After PCB SMT process, can customer measure TX or RX pins' signal level to determine it's a good or FA board without transmitting real signals?

If the description above is not clear or further information is needed, please let me know.

Thanks very much.

Vincent Chen