Hi,

We are seeing high field failure rates on a board that uses the TUSB4020BI. Hoping you can help us understand what is going on.

Background:

This is a rugged field (highly custom) application where many small data recorders (nodes) are brought into a central location to dump their data. This central location is typically a trailer of some sort that is somewhat environmentally protected. The nodes are loaded into racks to download data. The racks use several PCBAs, each with a TUSB4020BI to communicate to two nodes. So nodes are constantly being inserted and removed from the racks. The node is self powered so the hub TUSB4020BI is not doing any power control to the attached nodes, only high speed USB communications.

Failures:

We have started to see many boards that were previously working OK to suddenly stop connecting to a node as it is inserted. So far it has only been one of the two downstream ports (but can be either one) and the other port remains unaffected and working normally. SW or hard (power) reset does not recover the port once it fails. A failed board can be moved to a different location and the failure follows the board, so doesn't seem to be an issue with the Linux PC and main hub it is connected to. These boards do have a EEPROM for custom info but it seems to be OK. We have tried reprogramming the EEPROM, but this still does not fix the failure.

Debugging:

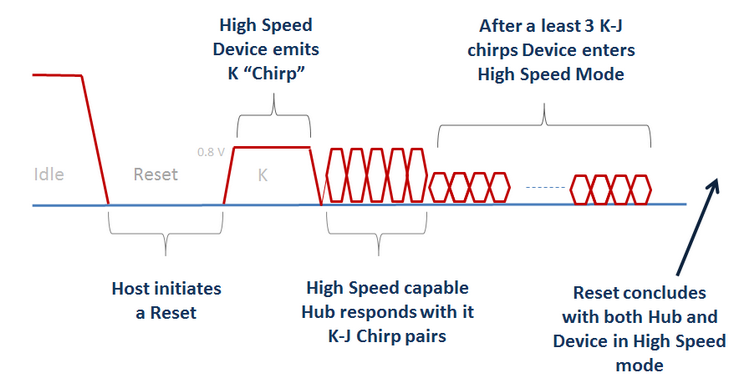

The failure is during the high speed device detection and speed negotiating phase. Testing on a Windows 10 PC reports a "Device Reset Error". I have looked at the signals on DP and DM with a scope and also connected a USB protocol analyzer to debug. This is what the typical high speed detection should look like:

And this is what I see on working ports.

On a failed port I see:

1) The initial IDLE state with the device pulling DP high and DM is low. This is OK

2) The TUSB4020BI hub then drives DP low with DM still low to start a reset. This is OK

3) Our HS device then responds with a K chirp of about 2mS. Device drives DP low and DM high, this is OK

4) The TUSB4020BI hub should then respond with K-J chirps on both DP and DM. This is where the failure appears to be. I only see the host K-J chirps on DP. DM is silent. It is almost as if the TUSB4020BI cannot drive the DM signal. The DP drive output seems to work OK.

We do have a ESD protection device on DP/DM (TPD2E2U06DRLR) but I removed it just in case it was the problem. Did not help and still have the failure. Nothing else is connected to DP/DM so it seems to be a failure in the TUSB4020BI DM output.

Any help would be appreciated.What failure modes could do this? Is it possibly ESD damage? How could we confirm this?

Just FYI, we inherited this board from another company. I found another thread on E2E from that company about other issues with this same board and TUSB4020BI. It can be found at the following link for more background info if helpful.

https://e2e.ti.com/support/interface/f/138/t/778963?TUSB4020BI-Downstream-port-s-become-unresponsive

Thanks,

Paul