Dear team,

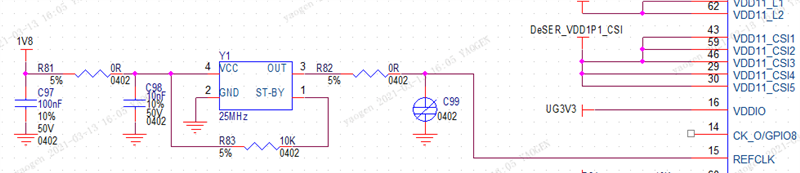

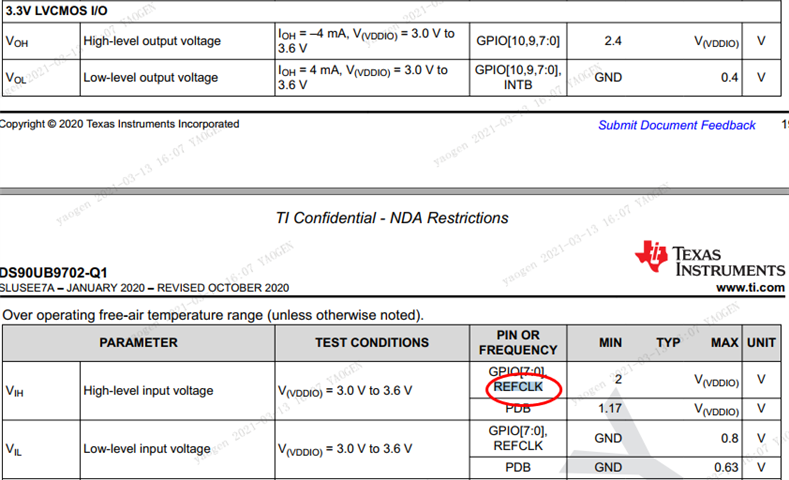

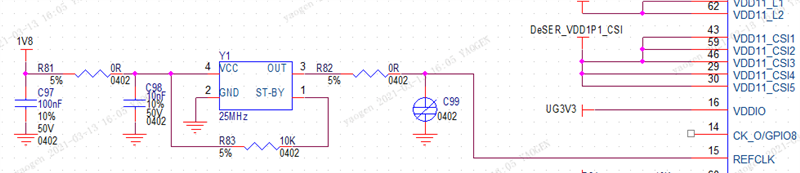

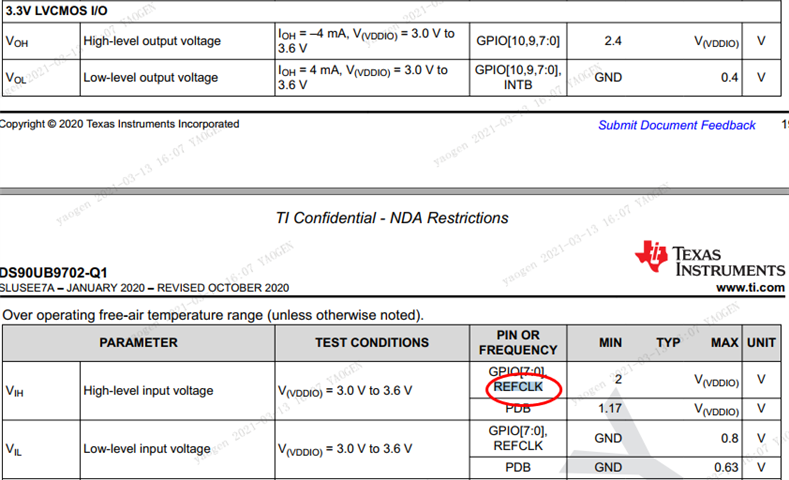

My customer sets VDDIO=3.3V & REFCLK power=1.8V. This setting won't work, right? In the datasheet, VIH must be larger than 2V when VDDIO=3.3V, so REFCLK power must be 3.3V, right?

Thanks & Best Regards,

Sherry

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Dear team,

My customer sets VDDIO=3.3V & REFCLK power=1.8V. This setting won't work, right? In the datasheet, VIH must be larger than 2V when VDDIO=3.3V, so REFCLK power must be 3.3V, right?

Thanks & Best Regards,

Sherry

Hi Sherry,

The refclk amplitude should be tied to your VDDIO, in your case, 3.3V.

Best,

Jiashow

Hi Jiashow,

Thanks for your reply!

My customer just found this error in the design. Currently our 960 can work normally under this condition, VDDIO=3.3V, REFCLK power=1.8V. According to datasheet spec, our 960 shouldn't work normally because REFCLK power=1.8V which is smaller than VIH=2V, but actually it works... We don't understand why 960 can still work here?

Now the customer prepares to do the DV test, and the Gerber file has been sent out. DV test will be delayed if change REFCLK power to 3.3V now, so my customer wants to know what the potential risk is under this condition(VDDIO=3.3V, REFCLK power=1.8V)?

Thanks & Best Regards,

Sherry

Hi Sherry,

I would suggest following the datasheet recommendations. It might work under the current customer use case but we are not guaranteeing the full operation of this.

Best,

Jiashow