Other Parts Discussed in Thread: TPS25750, BQ25792

Hello, guys!

We are currently designing a device that will be powered with three 18650 cells connected in series - 3S1P configuration.

Consequently, a PD controller will be needed to boost VBUS voltage above 5V if we want to charge three 18650 cells. On the other side, we want to use the same USB-C connector (VBUS, D+/D- lines) for connecting our Host MCU (supports only USB2.0) with the PC.

When the PD charger is connected to the USB-C port and when we boost VBUS to ~12V in order to start the battery charging process, this would immediately burn our Host MCU that can tolerate up to 5.8V on its VBUS input. Is there any possibility to avoid this scenario?

Do we always start with +5V on VBUS pins even if we connect the PD charger to the USB-C port and then it is the PD controller that requires boosted voltage on VBUS during the negotiation phase (over the CC interface)?

Would it be possible for PD controller to inform the Host to disconnect itself from the VBUS rail (e.g. with the help of a load switch) before PD charger starts with the charging phase?

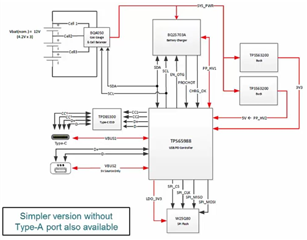

I came across your webinar about USB-C and Power delivery (link). There is a reference design I found that contains all the pieces we need in our system:

- PD controller - TPS65988

- Battery Charger - BQ25703A

- Gas Gauge & Cell balancer - BQ4050

- Type-C ESD protection circuitry - TPD8S300

However, this seems to be slightly overcomplicated for our use case. We would need a simpler PD controller. Moreover, this reference design is from October 2017.

Would you be so kind to recommend us the key parts in reference design (PD controller, charger, Gas Gauge...) that are more up-to-date?

Thank you very much for your time and efforts.

Sincerely,

Bojan.