Measuring SN74AUP1G17 Low-Power Single Schmitt-Trigger Buffer Delta Icc with 3.3V supply and 2V input results in >150uA of current.

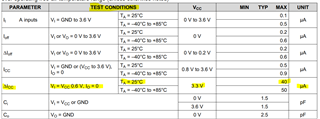

Datasheet says 40uA max Delta Icc at room temp.

Device is mounted to a breakout board. Current is measured with Keysight N6705B with N6781A SMU. input voltage is varied with second SMU in same chassis with shared GND.

Current is as expected when in normal Vih/Vil range, but not in region where Scmitt-Trigger is active.

Am I measuring this wrong? Why is it 3-4x the max listed in the datasheet?