Other Parts Discussed in Thread: SN74AHCT1G14, TCAN330, SN74LVC1G07, SN74LVC1G17

Hello,

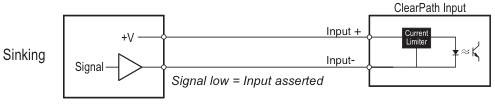

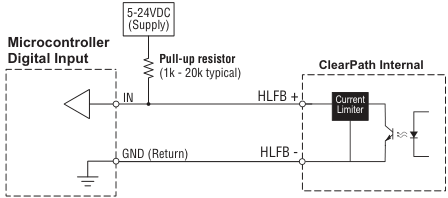

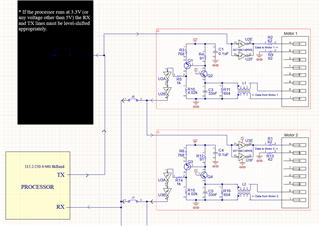

An actuator vendor provided schematics to interface circuitry between an MCU (on our end) and the actuator serial interface on (their end). The schematic sheets suggest level shifting is required for any voltage other than 5V. Looking for help and/or suggestions with the following:

1. I have been trying to convince myself that the provided circuity could very likely be reduced with lower count parts taking advantage of smaller level shifting and/or isolation ICs etc... rather than keep the vendor reference design AND add level shifting to the front end of their existing design as noted in the schematic. Snippet below.

2. If the assumption in 1 above is incorrect would it suffice to use a TXB102 part or similar?

Goals:

- Build these circuits into a custom PCB that will serially chain 8 motors so smaller component count would be desired. Each motor will require one instance of the circuit and chained as shown in the snippet.

- From the schematic notes 115.2 ,230.4, and 460.8 kbps are options. It would be great to continue to support the highest data rate. I realize the TXB102 does not meet this requirement hence I just used this PN as a baseline for the level shifting series.

Some Design Context:

- Our source 3.3V UART from out MCU.

- The actuators are generally designed/used in industrial environments - very noisy and very long cable lengths 10s and 50s of ft -

- Our application environment is an adoption to robotics - yes probably noisy but with very short cable runs like 4ft or less.

Looking forward to the discussion and ideas and thanks in advance for the help.

Cheers,

Wess