Tool/software:

I am seeking clarification regarding the difference between the two types of parts identified as 5962-8762401DA and 5962F8762401DA. Specifically, I would like to understand the following:

-

What are the differences between the (-) part and the (F) part?

-

It is understood that the (F) part and the (-) part are the same device (die revision/package), but are there any flows or processes that differ from standard process manufacturing for lot selection, testing, and manufacturing to produce (F) parts? If there is any difference in manufacturing process distinguishing the two parts?

To be more specific, the current lot-based assurance seems to exceed the program requirement of my project.

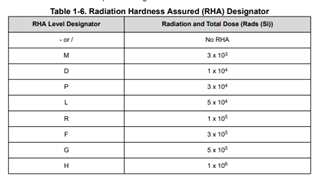

Since our application does not involve environments sensitive to Total Ionizing Dose (TID), we are considering whether the lot-level radiation margin of 300krad for the F part is necessary.

Therefore, I would like to confirm some level of confidence based on the reliability of the manufacturing process and material quality to ensure that it is acceptable for use.

Could you provide any available data on the TID endurance of the standard (-) part, such as test reports or characteristics of the die?

I understand that Radiation Hardness Assurance (RHA) is not applicable to the standard part.

However, if the manufacturing process and materials are the same, I thought it may be suitable for application in a less senstive(<10krad) space environmnet, so I inquired to confirm the accuracy.

Best regards.