Tool/software:

App Note: Optimizing Board Design for Supply Constrained Environments

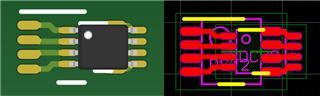

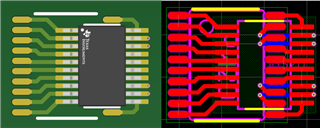

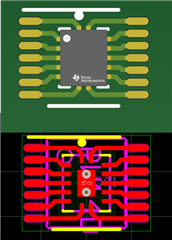

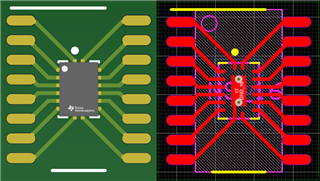

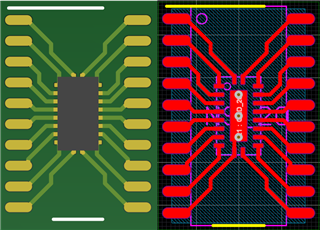

Dual foot-printing packages is the practice of overlaying a package's layout on top of another package. This allows more flexibility in system designs when supply issues are a main constraint.

The following are some combinations of packages that are recommend from our team. If there is a combination not listed, this does not mean it cannot be dual foot-printed. In general, there is nothing stopping any two packages from being foot-printed together. However, clearance rules will still need to be observed. There will be at least 5 mil clearance between any traces.

PW (14/16) -> DYY (14/16)

PW (20) -> DGS

PW (14/16) -> BQB (14) / BQA (16)

NS (16) -> BQB

NS (20) -> RKS

DBV -> DCK

DCT -> DCU