FAQ: Logic and Voltage Translation > Input Parameters >> Current FAQ

The most common example of this question comes from the fact that Standard Logic devices are specified at 1.65V, 3V, and 4.5V, however most engineers use our devices at 1.8V, 3.3V, and 5V.

Supplies are not perfect in any system -- they can fluctuate up or down significantly. MOSFET resistances increase at lower voltages, so the datasheet specifications are not tested at the nominal supply values , but at approximately 10% below nominal. I can't tell you why it's not exactly 10% -- these values have been used for decades and have become standardized throughout the industry. At 5V, it's exactly 10% (0.5V), but at 3.3V it's rounded to ~9%. At 1.8V it's ~8%. My assumption is that these values were rounded a bit to give easier values to work with -- 1.62V isn't as "nice" of a number as 1.65V, and in the end, they both achieve the same goal, which is to provide a 1.8-V supply lower limit for testing.

In many cases, the best option is to use the datasheet values for your design -- even if you know your supply is exactly 3.302V and will never change. They provide a 'worst case' value that will prevent errors in the design.

If, for some reason, you really need a value between those given in the datasheet, linear interpolation is the TI approved method for getting intermediate points. You might be saying "but not all those specs are linear" -- and you'd be right. The fact is though, that across a small range (for example, between 1.65V and 3V), the variation from linear will be minor, and the datasheet values provide some headroom to the specifications. This method gives a safe approximation that is backed by TI and our characterization process.

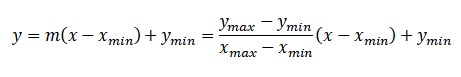

The equation for linear interpolation is:

Most typically, the "x" values will be the supply, and the "y" values will be the spec, with "y" being the value you are trying to get, and "x" being the specific supply value at which you are trying to get it.

I have already implemented this into an example Excel file if you would like to use that:

6303.linear_interpolation_v2.xlsx

If you need values beyond the datasheet specs, for example, if you need a 5.1V value and the datasheet only gives 3V and 4.5V values, then linear extrapolation is used. The equation and method are the same as above, except your data point will be outside the range of the given supplies. I would recommend only doing this for values very close to the given datasheet specs, since this method becomes more inaccurate the farther the supply is from the given values.